This weblog post is written to celebrate the upcoming 10th anniversary of Vortex Bladeless, as a concept, and the 81st anniversary of the collapse of the Tacoma Narrows Bridge on 1940-11-07. I have watched videos documenting the bridge collapse many times, and shown these to students in science classes over the years. Unfortunately, I lacked the insight of David Yáñez who was able to see the potential of oscillations in the generation of electricity.

Preliminary considerations

Living on a cliff-face, the residents at Cliff Cottage experience some wind, but less than many people might expect. The one-word reason is updraughts. That is, when the wind hits the cliff, it is deflected upwards, and then over the house. While the residents have considered installing horizontal bladed wind turbines at the cliff-face to provide electrical power, that take advantage of these updraughts, there is probably too little energy to make any investment economically worthwhile.

For example, a product was being offered on Kickstarter. On 2020-09-29, Nick Hodges, founder of Halcium, in Salt Lake City, UT, launched a funding round for (yet another device referred to as) a Powerpod, which was described as the “safest, most powerful wind turbine in the world”. He set US$ 200 000 as a minimum goal. When the fundraising period ended at the end of 2020-10, the goal was not met.

The product offered by Hodges, was not ideal for Cliff Cottage. The wind we are interested in using comes from one direction only, so being able to take advantage of wind coming from anywhere does not offer any advantages.

A major problem with the Kickstarter launch was an amateur approach to the electrical technology. After reading a description of the project, one was left with more questions than answers. Hodges apparently has a degree in small business management and an MBA with a finance emphasis from Arizona State University.

As another resident pointed out to me, entrepreneurship requires three competencies, finance (and related areas of business management), marketing and technical competence. From the material presented, it was obvious that Hodges had marketing competence, but lacked science and engineering skills.

For example, he claimed that Powerpods are “cheaper than solar panels and more efficient in places that get fewer than 300 days of sun a year.” When examining this statement, it is difficult to understand the specific apples and oranges being compared and contrasted. The number of square meters of solar panels is unspecified. Wind speed is an unknown factor, and there didn’t seem to be any documentation that related wind speed to power produced, only an attractive graph comparing power from a Powerpod with power from a normal wind turbine, whatever that is.

The number of days of sun is an unusual metric. Sunshine duration in hours per year is more common, something that can be determined using a World Meteorological Organization (WMO) standardized Campbell-Stokes recorder, which has been in common use since 1962. In 2003, the sunshine duration was finally defined as the period during which direct solar irradiance exceeds a threshold value of 120 W/m2.

There are claims that each 1kW in the Powerpod wind turbine creates up to three times more power than a regular, mounted turbine. The extra power comes from the blade system in the pod. While there is a graph showing this magic, there appear to be no supporting documents. There are no wind speed or power measurements, In fact, the graph incorrectly expresses power in volts, rather than correctly in watts.

The Powerpod system uses 12 Volt components. These are typically used on recreational vehicles to be compatible with vehicle electrical power systems. While they are used in residential systems, 48 V is quickly becoming the new standard. In part, this is because of the high amperage involved with 12 or 24 V. Transmitting 960 W of power with a 12 V system involves wiring capable of transmitting 80 A. With 48 V this is reduced to 20 A. Of course, if this power has to be transported any distance, it will have to be even thicker. Thick wiring is expensive and difficult to obtain.

Hodges goes on to compare wind and solar energy. In Norway it costs from NOK 30 000 to NOK 120 000 to have solar cell panels installed on an average single-family dwelling. This is typically financed by re-negotiating an existing mortgage. On average, the payback time for such an investment is about 17 years. The life-expectancy of the solar cell panels is from 25 to 50 years, and manufacturers offer a 25 year product guarantee on the solar cell panels, so that house owners do not face additional risks. Inverters may have a shorter life-span, and are not usually covered by the guarantee.

Unfortunately, the climatic situation in Norway means that solar panels can only produce substantial quantities of electricity during the summer. It is not that the equipment doesn’t work in the winter. Rather, the sun is close to the horizon, and not visible for many hours. On the date of publication, sunrise was at 08:16, sunset will be at 15:41. This gives 7h24m 43s of daylight. At the winter solstice (2021-12-21) daylight hours will be reduced to 4h17m21s. At the next summer solstice (2021-06-21) there will be 20h53m32s of daylight. Selling power usually requires one to participate in a spot-market, where prices are usually low in the summer, but high in the winter. Despite this, most people who install solar panels in one form or another want to connect to the mains in order to to sell excess electricity, or to access electricity when there is a production deficit. Batteries could be used, but new batteries are expensive. Some people will decide to buy discarded batteries from electric vehicles and store electricity with these. This is a more common model for cabin/ vacation cottage solar panels, less common for primary residences, because the cost is too large in relation to potential savings. Once again, people have risk aversion.

Another approach is to produce electricity in the summer and store it until it is needed in the winter. While the return-on-investment calculation for this looks good, mainly because of the high price for electricity in the winter, a large battery capacity is necessary.

Hodges’ main goal is admirable. He wants to reduce dependence on fossil fuel. He wanted to use the $200 000 funding to mass-produce Powerpods. The money sought would cover the cost of having the product tested, the raw materials for products being sold as part of the kickstarter project, as well as factory tooling.

After reading the project description, I was not totally convinced that Hodges had a viable product, or the necessary skills to make one. Hodges should partner with someone who has the necessary electrical engineering skills. This would allow for the development of the entire infrastructure needed for off-grid power production. These will have to meet agreed standards. At a minimum this consists of battery storage, a suitable inverter and a net metering system to allow produced energy to be used in the residence, or fed to the grid (especially at peak times). The equipment must be able to handle abnormal situations, such as power surges and power failures. The system should also prohibit sending power onto the grid, when it is down, as this could be potentially dangerous for crew members working to restore power.

There are also a number of legal issues that have to be negotiated, including energy purchase and sales agreements, and liability (including liability insurance). The specifics vary from jurisdiction to jurisdiction. Thus, it might be appropriate for Hodges to restrict his sales to Utah, and to find other people to cooperate with in other states, provinces and countries.

At Cliff Cottage we probably won’t participate in such a project. Instead, we will work slowly and methodically to find solutions that meet our specific energy needs. As a first step this will involve measuring wind speeds at the cliff face, to determine if wind energy is viable. If it is, then this process will slowly intensify as we select a more viable solution.

A More Viable Answer

The Vortex Bladeless turbine, popularly referred to as the Skybrator, has its origins in 2012 after David Yáñez watched a video of the Tacoma Narrow’s bridge oscillating in the wind. Since then, Vortex Bladeless, a Spanish tech startup, has been working to produce electricity from oscillations induced by wind.

Vortex Bladeless is a vibration resonant wind generator: It does not rotate, and is not a turbine, in contrast to the common horizontal-axis wind turbines (HAWT) and less common vertical axis wind turbines (VAWT) that work by rotation. Instead, it harnesses energy by allowing a fibreglass and carbon fibre reinforced polymer mast to oscillate in the wind, taking advantage of von Kármán vortices that form when a moving fluid (air) passes over a slender structure (the mast). At the bottom of the mast, a carbon fibre rod moves an alternator to generates electricity.

Wind turbines have issues, including maintenance costs, amortization rates, noise levels, bird deaths and other environmental impacts. Remote locations can have logistics challenges, while their visual and aural impact on a location is not always appreciated. The mass (and dimension) of vortex generators, indicate that they will use less raw materials in their construction compared to rotary wind turbines of the same power. They have a low centre of gravity that allows for a smaller foundation and less wake turbulence. Thus, they can produce more power (greater energy density) per unit of land area.

However, the market Vortex Bladeless envisions if for a small wind-turbine alternative for the end-consumer market and for low-power systems. These are markets that are served poorly (or not at all) by larger-scale wind turbine manufacturers.

- Vortex Nano – 1 m high and 3 W nominal power output. For off-grid, low-power systems, especially with solar panels.

- Vortex Tacoma – 2.75 m high and 100 W nominal power output. For small-scale residential/ rural autonomous operation, with solar panels.

- Vortex Atlantis/Grand – 9–13 m high and around 1 kW nominal power output. For residential/ rural autonomous operation, with solar panels.

All of these are slender, vertical, cylindrical devices, composed of two main parts: a fixed base where the device is attached to an anchor, and a flexible mast which, acting as a cantilever, that interacts more freely with moving fluid (air) in an oscillating movement. The oscillator has no gears or moving parts in contact with each other, so there is no need for lubricants.

A linear alternator, with neodymium magnets and its stator is located inside the moving part of the device, converts mechanical to electrical (chemical) energy. During this process the alternator damps/ cushions the induced oscillation movements. These devices operate with minimal maintenance and operating costs.

Tacoma Narrows Bridge

There is 1.4 km of Puget Sound separating Tacoma from Gig Harbor. Yet, before the construction of the Tacoma Narrows Bridge, one had to drive 172 km between them. With the bridge in place, this was reduced to 13 km. The bridge also linked McChord Air Field near Tacoma with the Navy shipyard in Bremerton, both important elements of the American military’s infrastructure, and probably the most critical one that allowed the funding of the bridge. Washington States bridge engineer, Clark Eldridge, had proposed a conventional design for the state highway department and Toll Bridge Authority. However, the federal Public Works Administration, insisted that bridge engineer Leon Moisseiff, designer of the Manhattan and Golden Gate bridges, be hired as the lead consultant and designer, and to use deflection theory as the basis of the design, producing a lighter, narrower, more flexible and cheaper structure.

Construction of the bridge started in 1938 and took 19 months. When finished, the Tacoma Narrows Bridge had an 853-meter-long centre span, almost half its total length. It was the third longest suspension bridge in the world, behind the Golden Gate and George Washington bridges. It also had the smallest ever width-to-length ratio: 1 to 72. Even before the bridge was completed the bridge deck shook in a wave-like vertical motion. This earned the bridge its nickname, Galloping Gertie. The bridge opened on 1940-07-01.

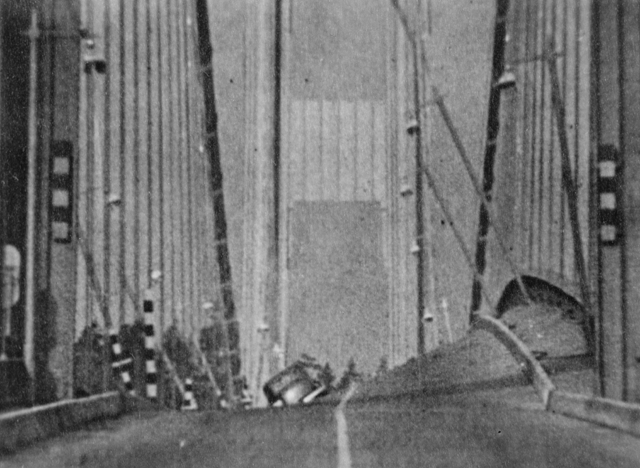

On 1940-11-07/ November 7th, 1940/ 7 November 1940, south-westerly winds, with gusts up to 68 km/h began to buffet the bridge. The deck began its customary rippling, bouncing up and down with more than a meter of displacement from its normal position at times. Shortly after 10:00 traffic was halted because of bridge deck oscillations. Soon after the bridge’s vertical movement was supplemented by a twisting motion that whipped the deck up and down to either side of the centre of the roadway. The twisting grew increasingly severe, with one sidewalk up to 8.5 meters higher than the other.

At 11:02., a 180-meter portion of the centre span gave way, crashing into the water below. Additional sections followed. The last major section fell at 11:10. With most of the centre span gone, all that was left were dangling suspension cables, a hole between the two towers and remnants of sagging side spans at either end of the bridge.

Earth magazine has an article that provides further information about this bridge failure.