In North America, a table saw is often used to cut dados (square sectioned grooves). A stacked dado blade set is a sandwich of blades to be fitted onto a table saw for making dados and rabbets. There are two rim (outer) blades. These differ from each other and are referred to as the left rim and the right rim blade, respectively. There is also a series of chippers, specially-designed blades that fit between the rim blades, as well as dado shims aka spacers, that lack any cutting features, but vary in thickness. They can be made of metal or plastic. These ensure that the dado is the precise width that is needed.

The arbour (the axis or shaft that supports and rotates the blades of a table saw) has to be long enough to accommodate the stacked dado blade set. This is the challenge with European table saws. Their arbours are too short to accommodate more than a single blade, and still allow the nut to be fully threaded onto the arbour when the blade is tightened. Thus, making dados is a task that is normally done with some form of router in Europe. The main problem with this approach is that there are is not an unlimited choice of router bits to select from.

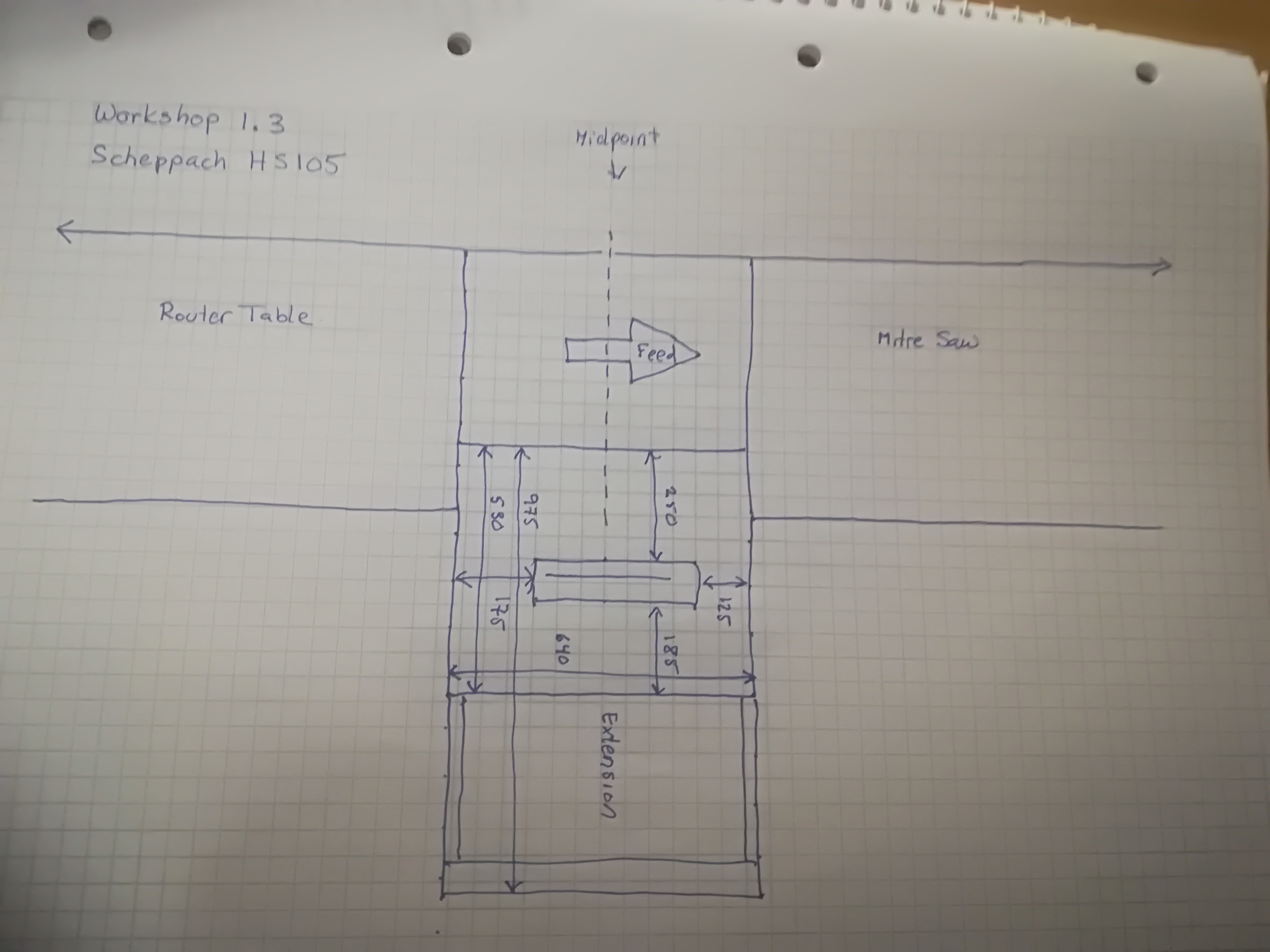

While most routers are portable machines, something approaching a table saw is also available, but with a rotating vertical shaft, rather than a horizontal shaft. The spindle moulder (British English)/ wood shaper (American English)/ router table (General) comes with a motor, frequently housed below the table surface.

The Scheppach HF-50 is a machine for DIY enthusiasts, rather than professionals. The author’s many different Scheppach tools, were all purchased for work on a house renovation project, and are not intended to be kept beyond its completion. These are not especially durable machines. The main reason the HF-50 was purchased, was the lack of choice. Professional machines cost five times more than the NOK 3 300 (USD 300) spent, and at least twice as much used. The HF-50, and many other machines, will be replaced by the end of 2023 with a CNC machine, probably with a router as well as laser cutter. It may even include a plasma cutter. Such a machine costs about 20 times the price of a router table, but will provide greater production flexibility.

In contrast to a router, stock (the unprocessed wood) runs along a vertical fence from right to left. Viewed from in front of the infeed, the cutter head can be described as a right-hand vertical side head. Other configurations include a bottom horizontal head, a left-hand vertical side head, and a top horizontal head. A single head moulder will only cut one surface at a time. It is common for multi-head moulders to have up to four heads.

The spindle is height adjustable from 0 to 40 mm. While most spindle moulders rotate between 3 000 and 10 000 rpm, the HF-50’s speed varies from 11 500 to 24 000 rpm, close to that found on a portable router. The cutters shanks have a diameter of 6 mm / 8 mm / or 12 mm. Power on the HF-50 comes from a 1 500 W motor. Other spindle moulders may have as little as 750 W, to as much as 5 000 W per head.

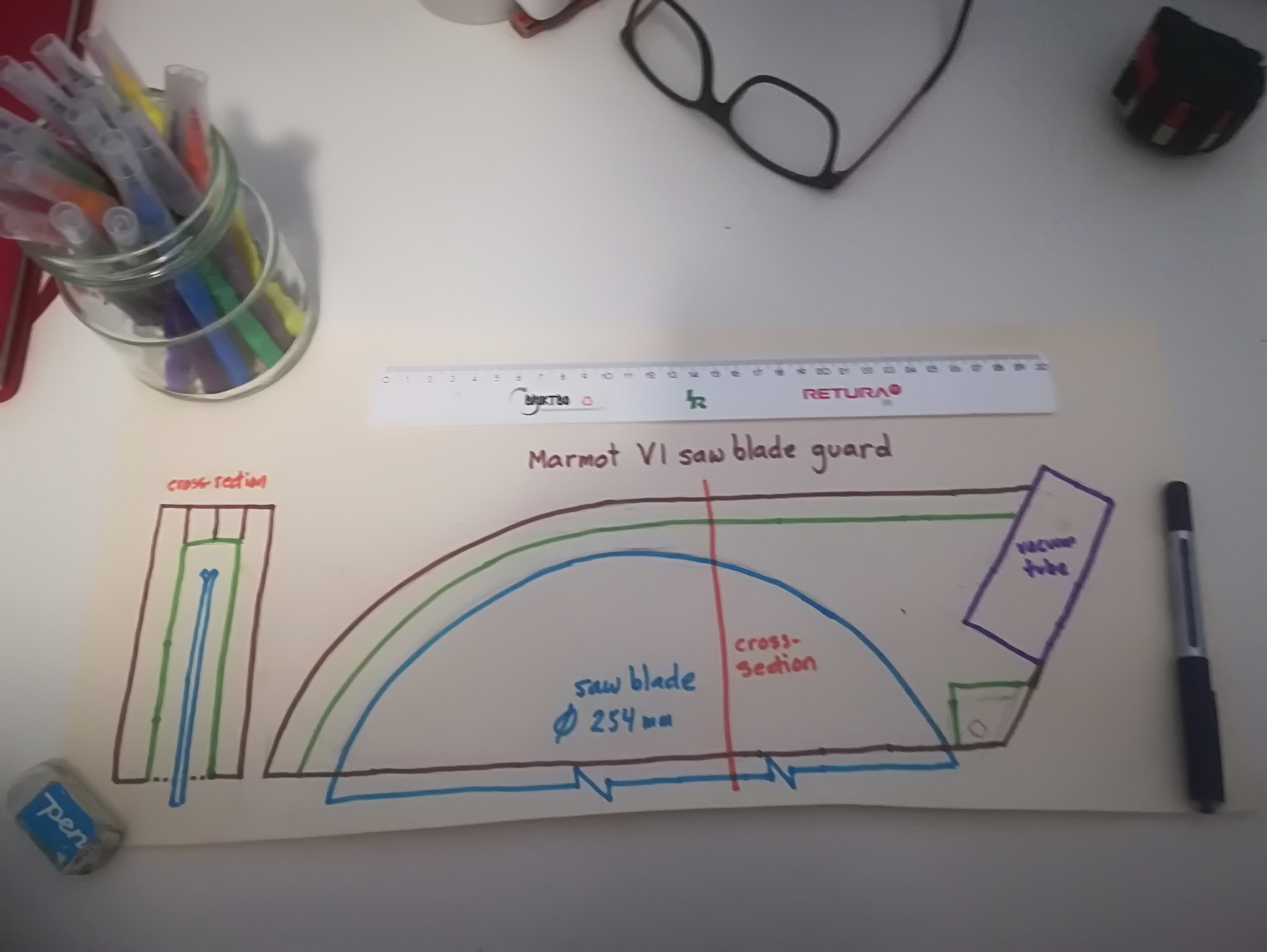

Hearing, eye and respiratory protection are necessary when using a spindle moulder. The machine itself is usually equipped with a guard above the cutter, to protect hands and prevent garments from being drawn into its blades. Hold-downs and feather-boards can also prevent injury.

There are two major jobs intended for the spindle moulder. The first is to use it to make drawers for kitchen cabinets. This will follow some of the advice of John Heisz in his video, How to Make Drawers the Easy Way, with additional information provided by Gary Katts in the video, The Quarter-Quarter-Quarter Drawer System. Quarter inch is translated as 6 mm.

The second is to make moulding that for LED strip lighting, that will be covered with translucent plexiglas. This is a relatively simple design, that will allow much of the house lighting to be DC powered. Electricity will be supplied using Power over Ethernet (PoE) standards. PoE cables are in place throughout the house.

In addition, I intend to make an oak table from counter-tops. Since the width of the table is 900 mm, while a counter-top is 600 mm, this means two edges will have to be planed, using a spindle moulder, rather than a jointer. This eliminates one more tools from the workshop, saving space.

After these three projects are completed there will undoubtedly be other projects that will use the capabilities of a spindle moulder.

Note: This post was originally started 2018-03-18 15:23:25. Its original title was Workshop Tools: Shaper.