Full disclosure. At one time, I had responsibility for laundry, washing the family clothes/ bed linen/ textiles more generally. Unfortunately, my supervisor was not totally satisfied with the results, and I was fired from that position. Since then, and a couple of washing machine purchases later, that same supervisor is still in charge of laundry. Thus, this weblog post is being written as a spectator to the washing process, and not as an active participant in it.

What does environmentally friendly clothes washing look like? At one time, say, until minutes before starting to write this post, I thought it was all about energy savings. Lower temperatures used less hot water. Now, I find that there are other considerations. A University of Leeds in-house article points to research on this topic.

Lucy Cotton, Adam S. Hayward, Neil J. Lant & Richard S. Blackburn, have written an article, “Improved garment longevity and reduced microfibre release are important sustainability benefits of laundering in colder and quicker washing machine cycles”, that appeared 2020-01-14 in Dyes and Pigments. The article’s abstract can be found in the last paragraph of this weblog post.

Clothes and bed linen have to retain their integrity: neither falling apart, nor sending microfibres into waste water, nor sapping textiles of their colour, nor shrinking. For decades now the washing temperature chez McLellan has been set to 50C, unless there is some specific reason for decreasing/ increasing it. The most common reason for decreasing the temperature, is that the laundry load consists of garments made from wool. These items are washed at 30C. We use Milo, a laundry liquid, for wool (and silk) textiles. We use Neutral Colour, a laundry powder, for everything else. One reason for increasing temperature could be an attempt at stain removal.

A Guardian article about the research, explained that 25C was selected as the working temperature, because that is a common inlet temperature for water in washing machine in England – the natural, unchilled and unheated temperature at which the water enters the drum. I am looking forward to gaining some empirical data on Norwegian inlet temperatures. Currently, my estimate is that they are closer to 10C. A post will be written after data has been collected and analysed, with updated information.

Cotton’s research did not test cleanliness at different temperatures. Instead, it examined the release of dye (desorption) and microfibres from a range of consumer clothing. So, the pesky question remains: Can cleanliness happen in a cold, quick wash?

Cleanliness has a social and cultural dimension beyond the requirements of hygiene for practical purposes. Numerous internet sources are quick to state that higher washing temperatures improve cleanliness, but there is seldom any empirical data associated with it. There seems to be a common expectation that cleaning will not only remove dirt, but also kill microbes. Some people may expect textiles generally, and clothes especially, to have a pleasant odour, others may want textiles to be odour neutral. Some may even expect a miracle and have white (or more correctly, some version of off-white) whitened/ lightened/ bleached.

Yet, excessive cleanliness may not be a virtue. The hygiene hypothesis, developed by David P. Strachan holds that environmental microbes help develop the immune system; the fewer microbes people are exposed to in early childhood, the more likely they are to experience health problems in childhood and as adults. So, it might be a good idea to reduce washing temperature, to avoid killing so many microbes.

However, it may be suitable to wash clothes and bed linen at higher temperatures when people have been sick with contagious diseases, but to use lower temperatures more generally. The instructions on Neutral Colour specifically state that 60C should be used for washing bed linen, if the user is allergic to dust. The instructions on Milo state that both 40C and 30C can be used.

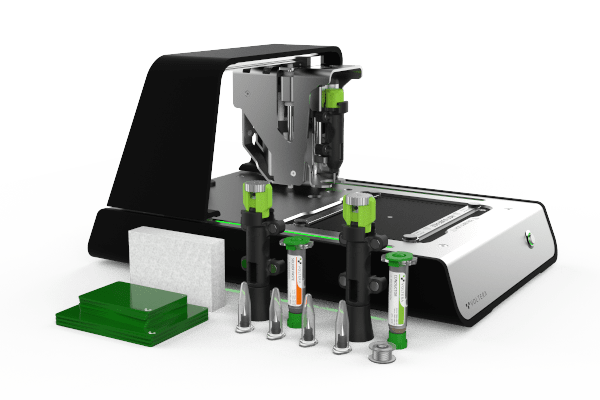

In an attempt to get empirical data on the relationship between cleaning effectiveness and washing temperature, one article explained the futility of the effort. “No more washing: Nano-enhanced textiles clean themselves with light.” Researchers at the Royal Melbourne Institute of Technology (RMIT) University in Melbourne, Australia, have developed a cheap and efficient new way to grow special nanostructures—which can degrade organic matter when exposed to light— and to incorporate them onto textiles. They are working at producing nano-material enhanced textiles that can spontaneously clean themselves of stains and other dirt when exposed to light, artifical (as in lamp) or natural (as in the sun).

Then, Wikipedia writes: “Animal studies indicate that carbon nanotubes and carbon nanofibers can cause pulmonary effects including inflammation, granulomas, and pulmonary fibrosis, which were of similar or greater potency when compared with other known fibrogenic materials such as silica, asbestos, and ultrafine carbon black. Some studies in cells or animals have shown genotoxic or carcinogenic effects, or systemic cardiovascular effects from pulmonary exposure.” It is definitely a hint that relying on nanoparticles, may not be the way to go.

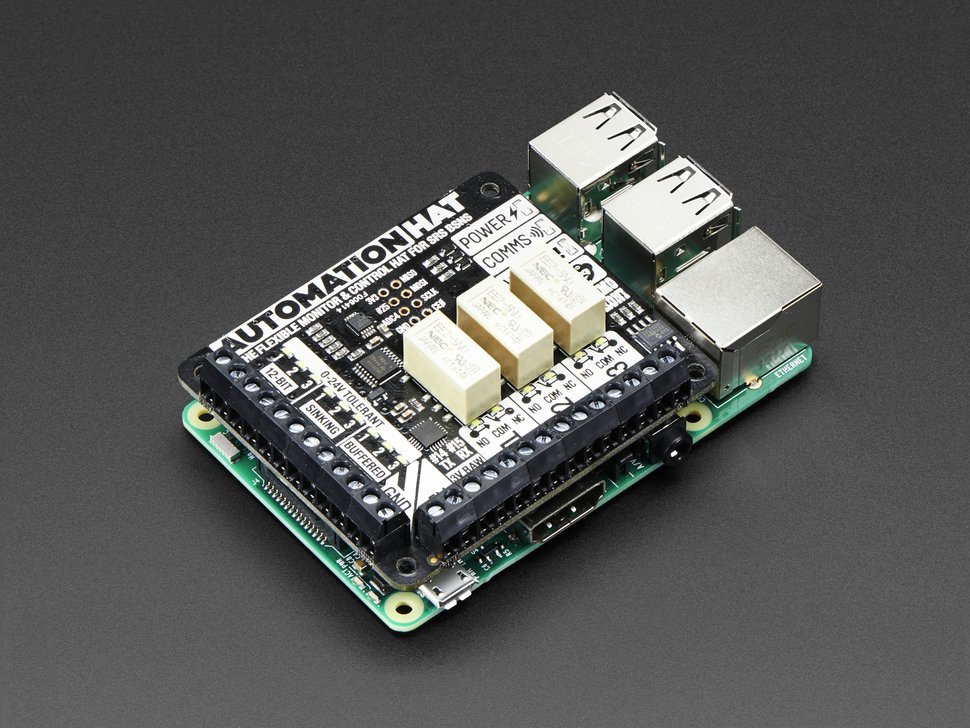

Domotics

Domotics, or household automation, is defined in an earlier weblog post. The main concern there was with room controllers. However, domotics intersects many different areas. Its early history, began with labour-saving machines/ devices, frequently electrically powered. Thus, initial advances were dependent on electric power reaching the houses of consumers.

In this post, laundry represents a very specific yet important application of domotics. Most people have a concern about the cleanliness of their textiles, but there needs to be a middle ground. People can be too slovenly or too finicky. Neither extreme is particularly good.

It can be difficult to date the first washing machine. Progress and significant developments occurred in 1691/ 1767/ 1862/ 1904/ 1937, depending how one defines a washing machine, and one’s expectations from it. However, it is not until the late 1940s, that one finds machines vaguely similar to today’s.

In Europe, washing machines have to meet an assortment of standards including 1. washing performance (A to G) 2. spin drying performance (A to G), 3. energy consumption (A+++ to G), and 4. waste water filtration. In addition to these, products must also be labeled to show capacity (in kilograms), water consumption (in litres), noise while washing and noise while spining (both dB (A)).

Only washing machines with category A performance in terms of washing and spinning, are allowed to be sold in Europe. This is because of an unexpected consequences of the earlier focus on energy consumption: Reduced rinsing after washing saved water and energy, but left more detergent residue in clothes, which created health problems, especially for people with allergies or sensitivities.

The waste water filters ensure that hazardous chemicals are not improperly disposed of, or allow feces and other waste to enter the washing machine with back-flow through the waste water line.

Most washing machines in Europe are connected only to cold water, which after filling uses internal electrical heating elements to heat the wash water, to 95C, if desired. This may be useful in certain situations, either to kill pathogens, or to improve detergent cleaning action. These machines can use detergents formulated to release different chemical ingredients at different temperatures, allowing different type of stains and soils to be cl eaned as the water is heated.High-temperature washing uses more energy, and may damage fabrics, especially elastics.

Temperatures above 40C inactivating biological detergent enzymes. Thus, if these are used, temperatures should be kept below 40C. Front-loaders used to need low-sudsing detergents, because the drum’s tumbling action caused over-sudsing and overflows. This is no longer an issue, if one reduces the quantity of detergent. This will not lessen its cleaning action.

Characteristics of some modern washing machines offer:

- Delayed execution settings, with a timer to delay the start of the laundry cycle.

- Time remaining indicator.

- Predefined programs for different laundry types.

- Rotation speed settings.

- Temperature settings, including cold wash.

- Child lock (some machines).

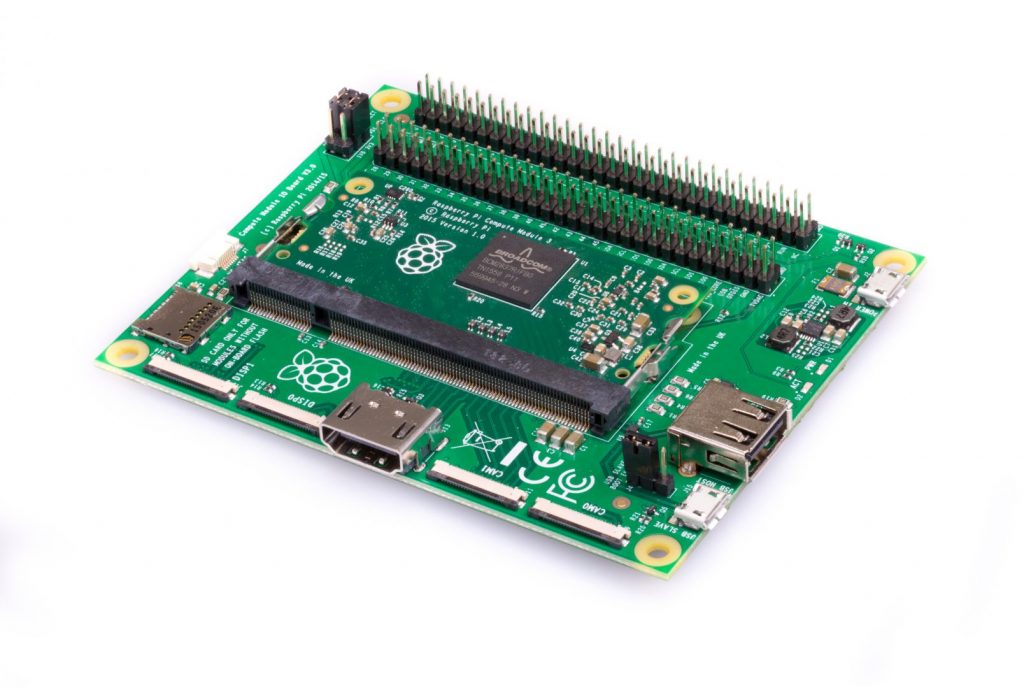

- Microcontrollers have been used for timing processes since the 1990s. These are more reliable and cost-effective than electromechanical timers.

- Touch panel displays have been in use since 2010.

- LG Electronics invented a direct drive motor system in 1998, with the stator attached to the rear of the outer drum, with the rotor mounted on the shaft of the inner drum. It eliminates a pulley, belt and belt tensioner.

- Electronically controlled motor speed.

- Hydraulic suspension, with freely moving steel balls contained inside a ring mounted at the front and back of the to balance the weight of the clothes.

Other innovations include:

- Water jets/ sprays/ showers and steam nozzles. These claim to reduce soil and reduce washing times. Water jets use recirculated water from the bottom of the drum.

- Titanium/ ceramic heating elements claim to eliminate calcium build up and can heat water to 95C.

- Automatic dispensers allow users to fill or replace tanks with detergent and softener but transfers dosage control to the washing machine.

- Detergent dilution is used to prevent detergent from damaging fabrics.

- Pulsators are mounted on a plate on the bottom of the drum. When the plate spins, the pulsators generate waves that help shake soil out of the fabric.

- Mechanisms can be installed to remove undissolved detergent residue on the detergent dispenser.

- Smartphones can be used to troubleshoot problems. LG Electronics LG’s approach involves sending signals that can be received by a phone. These signals are interpreted by an app. Samsung Electronics’ approach involves the user photographing the washer’s time display with a phone. The problem and steps to resolve it are displayed on the phone itself.

- Some washing machines are Near-Field Communication (NFC) enabled. These allow automatic and fast connections, wireless data transfer and identification. Its downsides include limited throughput, limited range and potential security vulnerabilities.

Comparison of domestic washing machines. Front-loaders are usually considered better than top-loaders.:

- Front-loaders usually have lower operating costs than top-loaders.

- Front-loaders usually have a lower total cost of ownership compared to top-loaders.

- Front-loaders tend to have more advanced features such as internal water heating, automatic dirt sensors and high-speed emptying compared to top-loaders.

- Front-loaders usually use less energy than top-loaders.

- Front-loaders usually use one-third to one-half the water used by top-loaders.

- Front-loaders usually use less detergent than top-loaders.

- Front-loaders can spin at 1 400 RPM while top-loaders have a maximum speed of about 1140 RPM. Spin speeds and drum diameter determine the g-force working to removes residual water, allowing textiles to dry faster. This also reduces energy consumption if clothes are dried in a clothes dryer.

- Front-loaders have longer cycle times than top-loaders, in part because top-loaders emphasize operational simplicity.

- Front-loaders use paddles in the drum to repeatedly pick up and drop clothes into water for cleaning. Top-loaders use an agitator or impeller mechanism to force enough water through clothes to clean them effectively. Washing with a front-loader decreases fabric wear compared to a top-loader. One proxy for clothes wear is the amount of link found on a clothes dryer lint filter. Lint is largely stray fibers detached from textiles during washing and drying.

- Top-loaders have greater difficulty cleaning large items, because these items may float on top of the wash water rather than circulate within it, and the agitator may damage delicate fabrics.

- Front-loaders are usually quieter than top-loaders, because the door seal insulates noise. They usually have fewer problems with load imbalance. Top-loader agitators usually require the use of a mechanical transmission, which generates more noise than front- loader drives.

- Front-loaders can be installed underneath counters. They can also be stacked with a clothes dryer to reduce their area usage.

- Front-loaders have simple motor drives in contrast to top-loaders that use mechanical gearboxes with increased wear and maintenance needs.

There are some areas where top-loaders are better than front-loaders.

- Front-loaders usually have a higher initial cost than top-loaders.

- Front-loaders are more prone to leakage. On top-loaders, gravity keeps water inside the drum. Previously, front-loaders require a gasket/ seal on the front door. This door had to be locked while operating to prevent it from opening. Many modern front-loaders use so little water that they can be stopped mid-cycle for addition or removal of laundry. The water level is below the door level.

- Top-loading washers are more tolerant of maintenance neglect.

Other comments

- All washing machines should have access to a a floor drain or an overflow catch tray with a drain connection.

- Front-loaders are more convenient for short people and those with mobility issues. Controls are front-mounted and the horizontal drum eliminates the need for standing or climbing.

- Risers, often with storage drawers underneath, can be used to raise the height of a front-loader so that it is at the user’s preferred heigh level.

Combined washer dryers, provide washing cycles and drying cycles in the same drum.

- The need to transfer wet clothes from a washer to a dryer is eliminated.

- It encourages overnight cleaning, which may help optimize power usage during low priority periods, but may increase the risk of fire.

- Drying uses more energy than using two separate devices, because a combo washer dryer not only must dry the clothing, but also needs to dry out the wash chamber itself.

- A combo machine can be fitted into the same space as a single machine, allowing it to be used where the lack of space is an issue.

- The washer may have a larger capacity than the dryer, decreasing their functionality.

A laundry centre is an appliance with two drum units. It is found in two varieties, one where the dryer and washer are beside each other, and the more common situation, where the dryer sits on top of the washer. Laundry centers have a single control panel for both units.

The Future

In the course of the coming years, I hope to look at many different household appliances, from a Domotics perspective. This includes revisiting washing machines, when I have learned more about how they will be operated. My most obvious limitation is my status as spectator, rather than participant, in the laundry cleaning process. To remedy this, I am going to ask reader with insights into washing clothes, to answer some open-ended, even vague, questions. These are preferred because they might actually lead to some insights.

- Tell me something/ anything/ everything about washing textiles that you want me to be concerned about!

- Tell me about yourself. What is your status? Participant/ Spectator/ Other (please specify). Are you female/ male/ non-binary/ a human bean? What is your approximate age? Have you ever had training to wash textiles? For example, did you learn anything at school about it?

- How are your laundry facilities organized? A separate laundry room/ part of a bathroom/ part of another room/ other (please specify). What type of equipment do you use for washing? Comments. What type of equipment do you use for drying? Comments.

- Do you use services outside of your residence to clean textiles? What services do you use? How often? Why? What are the challenges?

- Do you use the services of non-family members, who come into your residence to clean textiles? What services do they provide? Why do you use them? What are the challenges of using them?

- What are your textile washing objectives? Do any of them involve general dirt removal, stain removal, killing microbes, eliminating odours, adding odours, neutralizing odours, preventing shrinkage, preventing colour bleeding, increasing garment longevity, reducing microfibre release in wastewater, reducing operating costs, reducing energy consumption?

- What are your textile washing behaviours? For example: What temperature settings do you use? What cleaning chemicals do you use? What additional chemicals do you use? Do you have any special procedures used in particular situations?

- What would you like to automate in terms of laundry processes? Some choices include: start time, finish time, determining washing cycle, determining detergent quantities, automatic dosing of chemicals, other (please specify).

- Washing machine characteristics. Do you use a front-loader or top-loader, please specify brand, model and approximate age (I will try to find out other details from that). What do you like about this machine? What do you dislike about it? When do you expect to replace this machine? What do you think will be the reason for its replacement?

- Future washing machine characteristcs. What characteristics are missing in your current machine would you prioritize in your next machine? What characteristics are present in your present machine that you would avoid in your next machine?

- Did you want to tell me something else?

Abstract from Cotton et al.

The global impact of laundering clothing is significant, with high levels of water, energy use, and pollution associated with this consumer care process. In this research, the impacts of washing temperature and washing time on garment colour loss (dye fading), colour transfer (dye staining), and microfibre release were evaluated using retail consumer clothing. Significantly greater colour loss and greater colour transfer were observed for a 40 °C, 85 min wash cycle compared to cold-quick (25 °C; 30 min) cycle. Desorbing dyes were found to mainly be reactive dyes. From fundamental kinetic studies, it was observed that significant increases in both rate of dye desorption and total dye desorption occurred when increasing from 20 °C to 40 °C, but the difference in dye release between 40 °C and 60 °C was not as significant; the same kinetic trends were observed for dye transfer. Microfibre release was significantly greater for the 40 °C, 85 min cycle in comparison with the cold-quick cycle, and this effect continued with further washes. These results mean that reducing time and temperature in laundry could have a significant impact in terms of extended garment longevity and reduced dye and microfibre liberation into the environment, in addition to energy savings.