For the past three days I have spent my working hours fighting off a virus while pondering some fundamental concepts related to a community mechatronics workshop, that should be opening soon in Inderøy.

Ideally, this workshop should be all things to all people, or at least, a few different things to a few different groups of people. The challenge is, that one has only NOK 250 000 to equip the workshop, whereas one needs about NOK 1 000 000. The area is 70 square meters, and one room. What one needs is 200 square meters and five different rooms.

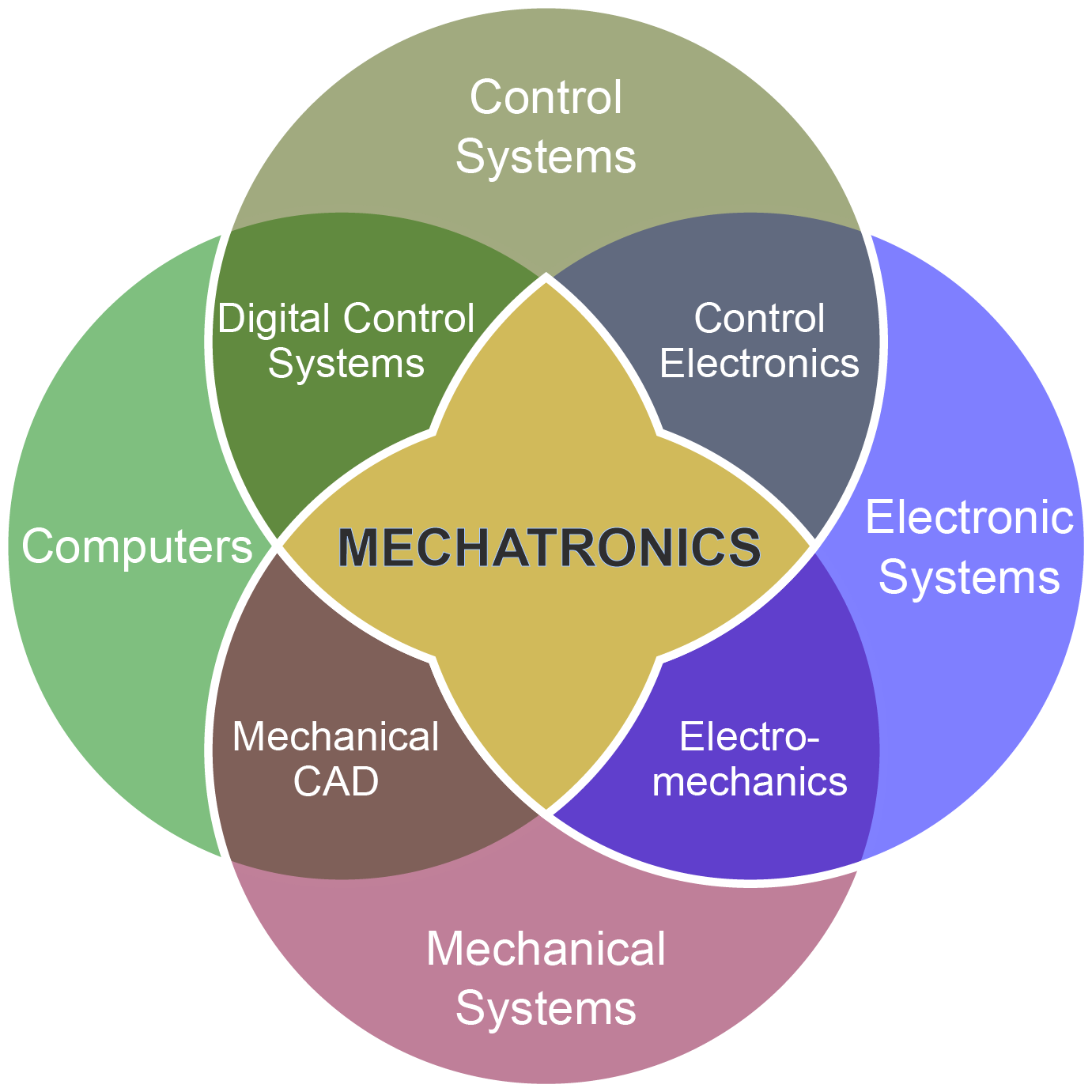

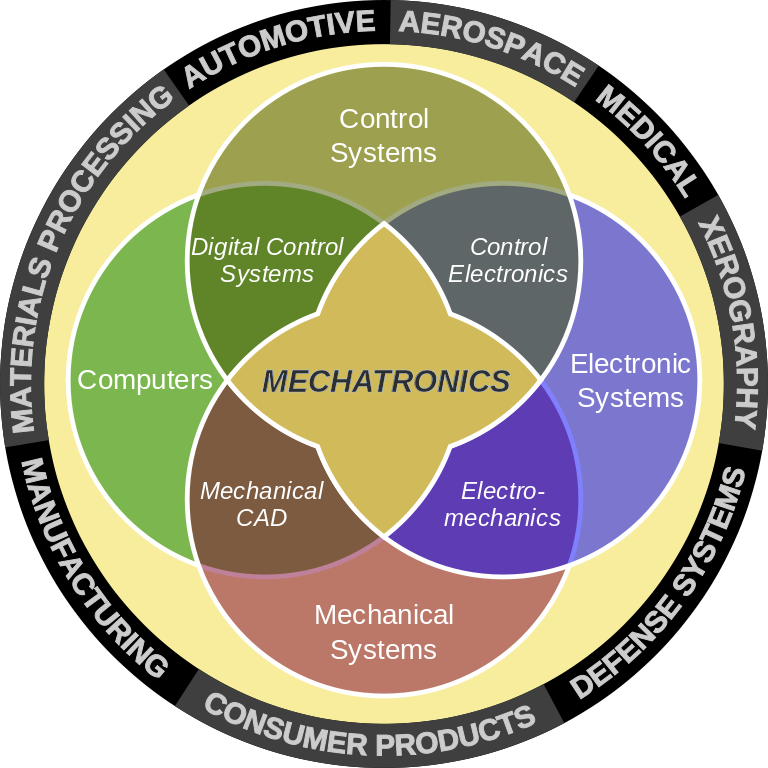

Rather than spreading investments over several fields, and ending up with nothing, a decision was taken to focus exclusively on mechatronics. Once this is in place and functioning well, then other areas can be prioritized at some unspecified point in the future.

Then there is the challenge of a name. What might seem like an obvious choice, a seemingly innocent term, such as maker space proves difficult to use in practice. Why? Well, maker is a political term, and is frequently usurped by people with vested interests. John Patrick Leary lists maker as one of his keywords, in his 2018 book, Keywords. Libertarians, in particular, have seized on this title. Other terms, such as hack space, have also been usurped, but by the socialist hoard, political adversaries of libertarians.

Before confronting the socialist hoard hackers, who are theselibertarians and what do they want? A quick, but necessarily incomplete, answer to the question is, followers of Ayn Rand (1905 – 1982). Admittedly there are exceptional libertarians who dislike Rand, but they are in the minority. Rand is known especially for two novels, The Fountainhead and Atlas Shrugged, and for a philosophical system she called Objectivism, that has inspired many libertarians. Mother Jones, the San Francisco based investigative magazine, remarked that “Rand’s particular genius has always been her ability to turn upside down traditional hierarchies and recast the wealthy, the talented, and the powerful as the oppressed.” (July-August 2009).

Rand is not noted for anything approaching political correctness. In her biography Goddess of the Market: Ayn Rand and the American Right, Jennifer Burns notes how Rand’s position that “Native Americans were savages” and that as a result “European colonists had a right to seize their land because native tribes did not recognize individual rights.” (p. 266) She has offered similar opinions about the Arab populations of the Middle East.

As David Harvey, in A Brief History of Neoliberalism (2005), argues, Neoliberalization’s primary accomplishment has been to “redistribute, rather than to generate, wealth and income” (p. 159). In particular, he points to privatization and commodification of previously public assets, which he describes as the “Commodification of Everything” in which all things are turned into things with that can have rents extracted from, including intangible ideas like originality, authenticity, and uniqueness, which “were never actually produced as commodities.” (p. 166) .

Much of the libertarian movement could be described as “me first”. It wants to reward the aggressive. At this point it could be appropriate for readers to take a pause, and read Debbie Chachra’s essay, Why I am Not a Maker: https://www.theatlantic.com/technology/archive/2015/01/why-i-am-not-a-maker/384767/

The point of the above essay is that a community workshop is not just a workshop for the few. There are a large number of social interactions that have to be facilitated. There are youth present who may be learning new skills, teachers who may be providing instruction, disabled people who may be in need of companionship, people of many genders who may want to create a new and for them, a more appropriate identity. While there may be people who may be making, there may be others who are repairing or repurposing or recycling or just reflecting on life.

I am particularly concerned that calling something a maker space, will in itself create an unintended hierarchy of users. In some maker spaces in Canada, it has been found that white, male youth, from privliged backgrounds, attempted to monopolize maker spaces, by defining themselves as its target group, and defining others as outside of that target group.

Such is the power of a name. I have previously argued for the use of a name that is the Norwegian equivalent of Velocity, a vector quantity that combines speed with direction. More importantly, it does not hint at what can or cannot be done in a workshop. There is no prestige to be lost if the organization changes direction. Velocity might be involved in mechatronics this year, then shift to fashion, cos-play and steampunk next year, before ending up as a videography group focused on rock musicals. It doesn’t make any difference, because the name is flexible.

Now it is time to look at more left-leaning hacker spaces. Left-leaning, but not necessarily egalitarian or diverse.

In V. Kostakis, V. Niaros & C. Giotitsas Production and governance in hackerspaces: A manifestation of Commons-based peer production in the physical realm? (2014) International Journal of Cultural Studies, Hacker space practices supposedly contrast with market-based maker space businesses in that they are more focused on for-benefit rather than for-profit projects but that for-profit motivations are not entirely absent. In this study of 23 semi-structured interviews with a sample of hacker spaces around the world found that money remains a peripheral concept only. Particpants are motivated by the social desire for hackers to have a ‘third place’ for social interaction. This refers to American urban sociologist, Ray Oldenburg (1932 – ) and the importance of informal public gathering places for a functioning civil society, democracy and civic engagement. In addition, there is the altruistic motivation of ‘making the world a better place’ through working on commons-oriented projects. However, it was also found that openness only applied in a limited sense. The barrier is not a door; it is social inclusion. In J. Moilanen Emerging hackerspaces–Peer-production generation Open Source Systems: LongTerm Sustainability (2012) pp. 94-111, 90 percent of respondents were male and 64 percent of respondents had a completed a post-secondary degree. Often hacker spaces are closed to non-members, most days of the week.

Collaboration and sharing were found to be important by six out of

seven participants as evidence of collaboration in the spaces. In addition, some hacker spaces were committed to sharing projects with Commons-based licenses and favored people working on collective projects over personal ones. There was also a wide variety of ‘innovative’ hardware and software produced by hacker spaces and showed the underestimated power of meaningful human cooperation. At the same time there was community accountability, communal validation and autonomy. Participants cited trust and accountability as important pillars of hacker space operation.

A workshop needs legal status and governance. Most are non-profit organizations governed by elected boards, This is one of the first things that has to be put into place. An alternative is to nest the workshop within an existing organization, such a municipal public library. It needs membership fees and/ or funding. Often membership fees serve as the primary income source for a space though different membership levels or sliding-scale pricing. Some spaces receive grants or donations, as is the case with the workshop in Inderøy.

Workshops need physical space and equipment. Most start small but can grow into large spaces. One major challenge is finding adequate and affordable space. There is also a need for a workshop to abide by legal safety and ergonomic standards. Workshops may have issues with building codes, including fire protection and ventilation systems. There is also a need for liability insurance and waiver forms for adult participants.

The creation of a workshop involves much more than a group of

individuals coming together to form a do-ocracy.

One major challenge is the inability for workshops to account/ bookkeep volunteer labour. It is far too frequently treated as a free resource without value. This is inappropriate. Personnel and mentor costs are valid costs. When local government is involved, they need to be efficient in allocating limited resources (even those provided by retired persons). Other underestimated costs have to do with externalities. Noise and physical damage are major concerns, given that workshops have noisier and messier activities. To reduce noise impact, workshops may have to be given insulated spaces and flooring, and by separated physically from other quieter activities.

Stakeholder support is another significant issue. It is important that workshop initiators communicate openly with everyone even remotely influenced by the workshop.

| Operational | Cultural | Critical | |

| Design | A | B | C |

| Produce | D | E | F |

| Interpret | G | H | I |

| Disseminate | J | K | L |

A: Use a variety of tools, modes, media, and materials to design texts and artefacts. Re-design texts and artefacts.

B: Understand design principles within a specific social and cultural context, bringing their own experiences to bear on the task.

C: Reflect critically on design principles. Choose modes, media, and materials to use for specific purposes (e.g., to entertain,persuade, etc.) and for particular audiences.

D: Use a variety of tools, modes, media,and materials to produce texts and artefacts. Re-use/ re-purpose/ re-mix texts and artefacts effectively.

E: Draw on own social and cultural experiences in the creation of texts and artefacts. Allow feelings and emotions to shape the production experience.

F: Reflect critically on the process of production,to ask questions such as (i) How do I want topresent myself and others in this text or artefact? (ii) What messages do I want to convey?

G: Access and understand modes/ media/ materials used in the production of a text/ artefact. Comprehend meaning, interpret through analysis,reflection, synthesis. Relate text/artefact to own prior understandingand experience. Move beyond a literal to deductive andinferential reading.

H: Draw on own social and cultural experiences in the analysis and interpretation of texts and artefacts. Participate with others in collective reviewand interpretation. Understand texts and artefacts in relation to the social, historical, and cultural contexts in which they were produced. I: Reflect critically on the text or artefact that is being engaged with, to ask questions such as: (i) Who produced this? (ii) What can be discerned of the producer’s intentions? (iii) How has the producer positioned the reader/ viewer/ user? (iv) How do issues of power work in this context?

J: Able to use a variety of tools, modes, media,and avenues to disseminate texts and artefacts.

K: Understand most effective means of disseminating texts and artefacts within the social and cultural context. Reach out effectively to diverse audiences tocommunicate meanings.

L: Reflect critically on modes of dissemination, to ensure most effective use of them.

Marsh, J.; Kumpulainen, K.; Nisha, B.; Velicu, A.; Blum-Ross, A.; Hyatt, D.; Jónsdóttir, S.R.; Levy, R.; Little, S.;Marusteru, G.; et al. (Eds.) Makerspaces in the Early Years: A Literature Review; MakEY Project; University of Sheffield: Sheffield, UK, 2017; pp. 75–79. Available online: http://makeyproject.eu/wp-content/uploads/2017/02/Makey_Literature_Review.pdf

To conclude. There are a wide range of issues in workshop governance that can emerge, many of which cannot be found in advance.