Everyone is on familiar terms with the watt, with the possible exception of American muscle car owners addicted to horse power. To help them enter a world free of fossil fuel, all they need to do is make a simple, if slightly inaccurate, calculation: 1 HP = 750 watts.

If one uses 1 watt for 1 second, then the amount of energy used is 1 joule (J). There are many other, but more confusing, ways to explain this energy transfer: the force of 1 (N) newton acting on that object through a distance of 1 (m) metre; (In electrical terms) the energy of 1 (A) ampere passing through a 1 (Ω) ohm resistor, with a voltage drop of 1 (V) volt, for 1 (s) second.

To be true to the SI system, the battery pack on your favourite vehicle should be expressed in joules, in precisely the same way that the power you purchase from your household electrical supplier, should also be expressed in joules. Instead it is expressed in an illegitimate kilowatt hours where 1 kWh = 3600seconds/hour x 1000 W/kW joules or 3.6 (MJ) megajoules.

The standard size of an EV is quickly approaching 60 kWh = 60 x 3.6 = 216 MJ.

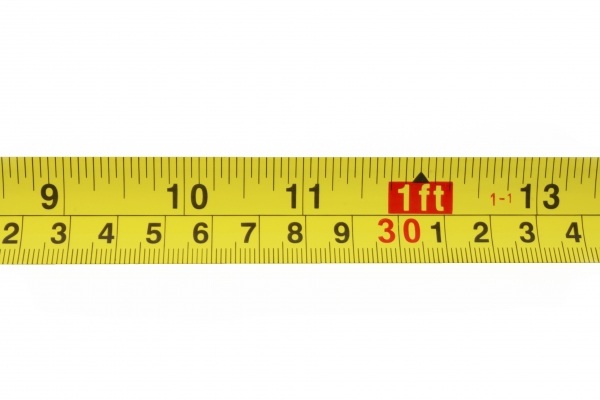

The limiting factor in most houses with respect to charging, is the thickness of the electrical wires. In general wiring requires cable with the following characteristics: 10A = 1.5mm2; 16A = 2.5mm2; 20A = 4mm2; 32A = 6mm2; 40A = 10mm2; 50A = 16mm2; 63A = 25mm2. Electrical input to Cliff Cottage uses 230 V, 3-phase, 25mm2 wiring, which provides a maximum of 25 kW of electrical power to be used for everything and anything, including EV charging.

Standards

Details about charging EVs are contained in several standards, including IEC 61851 and IEC 62196.

IEC 61851 Electric vehicle conductive charging system specifies general characteristics, including charging modes and connection configurations, and requirements for specific implementations (including safety requirements) of both electric vehicle (EV) and electric vehicle supply equipment (EVSE) in a charging system.

IEC 62196 Plugs, socket-outlets, vehicle couplers and vehicle inlets – Conductive charging of electric vehicles is based on IEC 61851.

The IEC 62196 Type-2 connector (Mennekes) is used for charging electric cars within Europe. The connector is circular in shape, with a flattened top edge and originally designed for charging at between 3 and 120 kW, using either single-phase or three-phase alternating current (AC), or direct current (DC). In January 2013 it was selected by the European Commission as official charging plug within the European Union. It is also the official charging plug in Norway. There is a transition period until 2020, which will allow other charging plugs to be used.

At the moment there are only three vehicles that use this plug as standard in Norway, Tesla Model S (up to 22 kW), Renault ZOE (up to 43 kW) and Mercedes-Benz B-Klasse (up to 11 kW). Because the requirements are more stringent for these chargers, Renault includes the electrical installation of its residential charging system in the price of the vehicle.

Norwegian requirements for charging of EVs have been specified in the following document (in Norwegian): https://www.dsb.no/lover/elektriske-anlegg-og-elektrisk-utstyr/tema/elbil—lading-og-sikkerhet/

While other makes and models currently use other charging systems. As new models are introduced, they will increasingly use Type-2 charging as standard. However, it is interesting to see that the Hyundai Ioniq and the Opel Ampera-e, both introduced in 2017, both come equipped with Combo CCD (DC) charging cables.

With Type-2 charging, the electronics is in the charging station (Mode 3) instead of in a box attached to the charging cable (Mode 2). This makes the cable cheaper to purchase and easier to handle. The contact is more robust, with minimal electrical, heat and fire risks.

Charging cables are needed in different variants depending on the electric car. At one end of the cable there will be a Type 2 connector to plug into the charging station. The other end has a contact designed for the specific electric car. Type 1 for Nissan, Mitsubishi, Kia, Peugeot and Citroën; Type 2 for BMW, Volkswagen, Tesla and Renault.

Charging Key and Chip

Access to charging stations is restricted, to prevent abuse. Most commonly access is dependent on the use of a standard key, or a chip. At most charging stations in Norway, use is free. Yes, that is correct. Vehicles gets filled up with electricity free of charge.

Because membership is included with most new EV purchases, it is standard practice for Norwegian electric car owners to be members of the Norwegian Electric Car Association (Norsk elbilforeningen) which, in addition to other services, provides members with both a charging key, as well as a charging chip, to give them access to charging stations throughout the country. While the key is used with most older charging stations, newer ones rely increasingly on a charging chip. Note: the charging chip will not work until it is registered with the individual charging operator!