The above title is designed to attract curiosity. Yes, it could be the name of a band, but it isn’t. Instead, it involves a proposal to take a potential recycling challenge and to turn it into an electrolyte for use in electric vehicles and integrated battery systems, equivalent to the Tesla powerwall.

Chitin is found in fungi, insects and crustaceans, such as crabs, shrimps and lobsters. It is a polysaccharide = sugar, that makes shells hard and tough. However, because large quantities of crustacean chitin is discarded as food waste, its use has been researched in a variety of applications. In biomedical engineering, for example, it is used as a wound dressing, or as an anti-inflammatory treatment.

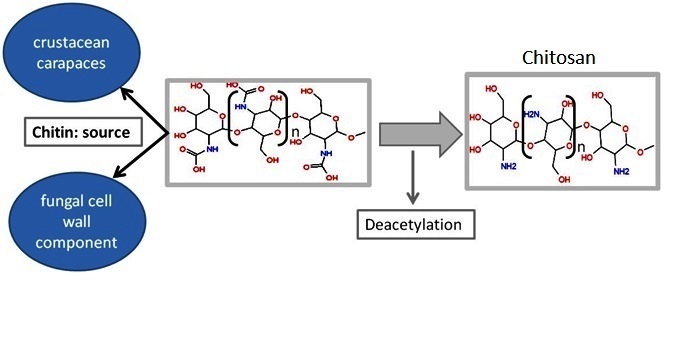

By adding acetic acid = vinegar, and processing it chemically (deacetylation), chitin can be synthesized into a gel membrane that can be used as a battery electrolyte = the liquid/ paste/ gel inside a battery that conducts electric current, using ions = positively and negatively charged particles that migrate towards the negative (cathode) and positive (anode) terminals, respectively, allowing it to store energy. This transformation is shown in the illustration below.

When this electrolyte is combined with zinc, it can create a cheap, non-flammable and renewable battery. After 1 000 cycles, the battery is still 99.7% energy efficient. This contrasts with Li-ion batteries, where such a large number of battery cycles can significantly degrade the battery. This is a rare battery characteristic, allowing these batteries to operate at high current density.

Another advantage of a chitin based battery, is that microbial degradation in soil can break down the battery in about five months, leaving zinc behind as a recyclable product.

Notes:

A University of Maryland press release, provides source information about the chemical process for anyone wanting to investigate this topic further.

Report Summary: Rechargeable aqueous Zn-metal battery is promising for grid energy storage needs, but its application is limited by issues such as Zn dendrite formation. In this work, we demonstrate a Zn-coordinated chitosan (chitosan-Zn) electrolyte for high-performance Zn-metal batteries. The chitosan-Zn electrolyte exhibits high mechanical strength, Zn2+ conductivity, and water bonding capability, which enable a desirable Zn-deposition morphology of parallel hexagonal Zn platelets. Using the chitosan-Zn electrolyte, the Zn anode shows exceptional cycling stability and rate performance, with a high Coulombic efficiency of 99.7% and >1,000 cycles at 50 mA cm−2. The full batteries show excellent high-rate performance (up to 20C, 40 mA cm−2) and long-term cycling stability (>400 cycles at 2C). Furthermore, the chitosan-Zn electrolyte is non-flammable and biodegradable, making the proposed Zn-metal battery appealing in terms of safety and sustainability, demonstrating the promise of sustainable biomaterials for green and efficient energy-storage systems.

While originally written 2022-09, publication of this post has been delayed to coincide with the Sharm el-Sheikh Climate Change Conference (COP27) held 2022-11-06 to 18. Politicians love such conferences, using them to receive undeserved publicity for making big promises, that they have no intention on keeping.

Because climate change is real, my hope is that people will:

- Use the coming year to find ways to reduce their carbon footprint.

- Hold their politicians accountable.

It is also hoped that some, select few people will find this battery concept so interesting that they will use some of their free time to develop an open-source battery. Should one be developed, I am interested in purchasing a 50 kWh battery system, to provide backup when the grid decides to go offline. I would also appreciate being kept informed of developments.

With this weblog post (#451) published, I have 52 posts scheduled, and most of those have been written! In addition there are 71 weblog posts, in draft format, that remain unscheduled. To ease that situation, weblog posts will be published twice a week, on Saturday and Sunday, until the end of 2022. This will add seven posts to the publication schedule. Some of these deal with the 2022 United Nations Climate Change Conference (Cop27), currently being held at Sharm el-Sheikh, Egypt.