A month ago today, I wrote about construction at our house. See: https://brock.mclellan.no/2018/09/22/a-work-in-progress/

Fjellheim (Mountain Home) as it once was officially called, Cliff Cottage as we refer to it, was built in 1963, to replace a log house set up on the same site the previous year, that had burned down.

The new house was undoubtedly financed by Husbanken (The Norwegian Housing Bank) which set strict limits on most features of the house, including size and choice of materials. The original house was 10 meters by 9 meters, or 90 square meters (968.75 square feet for those wanting excessive precision, and non-metric units). In reality, the original house had almost twice that area because a lower floor occupies about the same area. Indeed, the main entrance to the house is on this lower level. The house is built on a slope, so that there are no windows on the lower level at the back of the house.

Norwegian Post-war domestic architecture.

After the second world war, Norway was poor, and had to rebuild after its German occupation. Even in the 1970s there were housing shortages, and the country engaged in a number of (short-sighted) short-cuts in its rebuilding efforts.

The original owner of our house had made provision for the house to be expandable towards the fjord. They added a 6 meter by 10.5 meter cement terrace extending out from the house. Underneath this was a walkway to the front entrance, a carport, and a storage shed.

When new owners purchased the property in the 1970s, they had different (and to my mind, inferior) ideas about putting on an addition, and built a 15 square meter structure behind the original in the early 1980s, with a deviating roof slope, and non-standard ceiling height.

We moved into the house as renters 1 March 1989, and purchased it 31 December 1990, after the death of the second owner.

Because of a sag in the concrete terrace above the carport, we had half of the terrace sawn out and removed. I then rebuilt the carport and walkway (and half of the terrace) using wood.

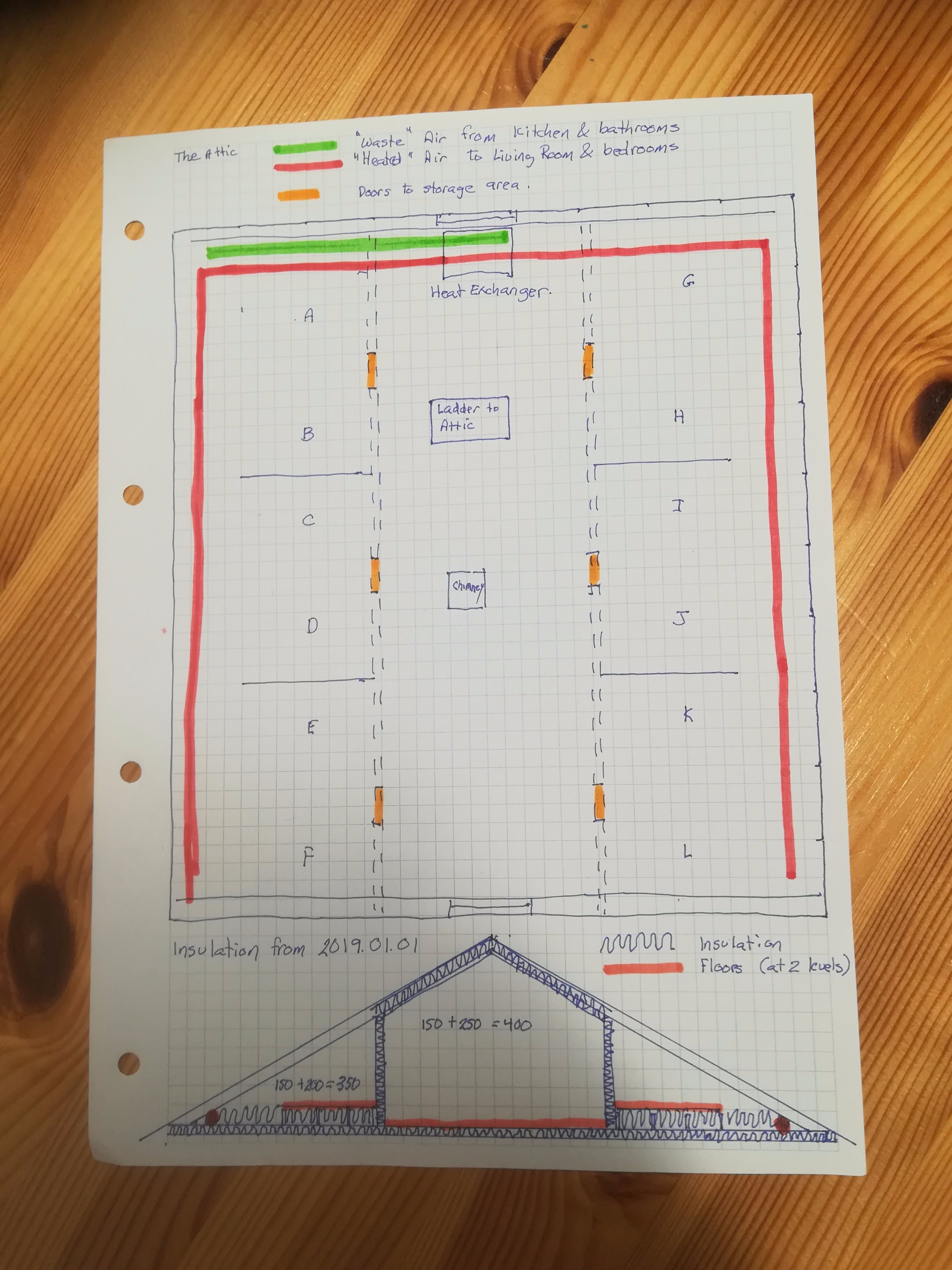

The Attic

In Norwegian, this style of attic construction is referred to as a kald loft, a cold attic. What this means is that the insulation is placed in the floor, between the joists, rather than in the ceiling, between the rafters. Theoretically, this means that the attic is as cold as the outside. This type of construction is no longer used, and in new builds with i-beam and other types of rafters, insulation is placed between them. Truss roofs have their own system.

The original insulation was supposed to be 150 mm thick. While it is sometimes that thick, much of the time it is only 100 mm. Sometimes it is even less. I found one area, normally hidden from view with stored materials, where tradesmen had removed insulation to put in a vent, and then not bothered to replace the insulation when they had finished. This problem was noticed only when stored items were moved, recently, into the centre of the attic. This is one reason why I want to do most, if not all, of the work myself.

The attic is effectively divided into three, by the two knee walls. The two outer thirds have had four additional 36 x 198 mm joists placed at 90° angles to the original joists to avoid cold bridges. These will be filled with 200 mm insulation. This takes up much of the space, but there is room at the edge for heating ducts that will supply the living room, dining area and bedrooms with “heat exchanged” filtered air.

In the center third of the attic, additional insulation will be added between the rafters. Because the room slopes, the effective thickness from 200 mm insulation is 250 mm. This provides a total of 400 mm of insulation.

The white pipe in the photograph will be providing cold input air to a wood stove in the living room.

Balanced Heat Recovery Ventilation

According to several sources, the ideal (read: cheapest) construction system for the installation of a balanced ventilation system is a cold attic. That is because there are few obstacles in the way of piping. The number and placement of new joists added in the attic, allows piping to reach the living room and bedrooms of the house, as well as rooms on the lower level.

In many cold climates, including Austria and Denmark, but not Norway, it is common for supply air to be transported underground in a pipe for some meters, so that heat from the earth can warm up the air. Typically, the pipe has a diameter of between 100 and 600 mm (4 to 24 inch), and slopes upwards towards the house so that any water drains out. There should be a MERV 8+ filter at the entry point, but even 1 mm insect netting will prevent many bugs and larger life forms from entering the pipe with the air. Smooth-walled pipe is preferred to prevent condensation and mold. These can be rigid or semi-rigid plastic, plastic-coated metal pipes or plastic pipes coated with inner antimicrobial layers. These are buried 1.5 to 3 m (5 to 10 feet) underground where the ambient earth temperature is typically 10 to 23 °C (50 to 73 °F) all year round in temperate climates.

While vendors of domestic heat exchangers delight in showing their units housed in kitchens and bathrooms, these are not ideal locations. Thus, the system planned for Cliff Cottage will be located in the attic directly above the main bathroom, which is located beside the kitchen.

Storage

I remember fondly ads for a moving company (Allied Van Lines?) who were keen to announce that they would keep other people’s junk away from your valuable possessions. Yes, it can be difficult to separate trash from treasure. Fortunately, most of the items in the attic only hold sentimental value.

Soon, there will six short, insulated doors, one in the middle of each storage area that measures 3 meters in length, by 1.8 meters in depth. Height varies from about a meter to 10 – 25 cm, depending on how it is measured.

The main challenge is being able to find something when it is needed. This is why the storage spaces will lettered from A to L. Each of the four people in our immediate family will be assigned two letter sections.