Paxster’s website begins with a boast: The best-selling Norwegian vehicle of all time! Production figures show this to be about 3 000 vehicles produced.

Paxster is a last mile delivery vehicle, from a transportation hub to a final household destination. In Norway, last mile implies that the vehicle can withstand rough road and weather conditions. Think ice and snow, respectively.

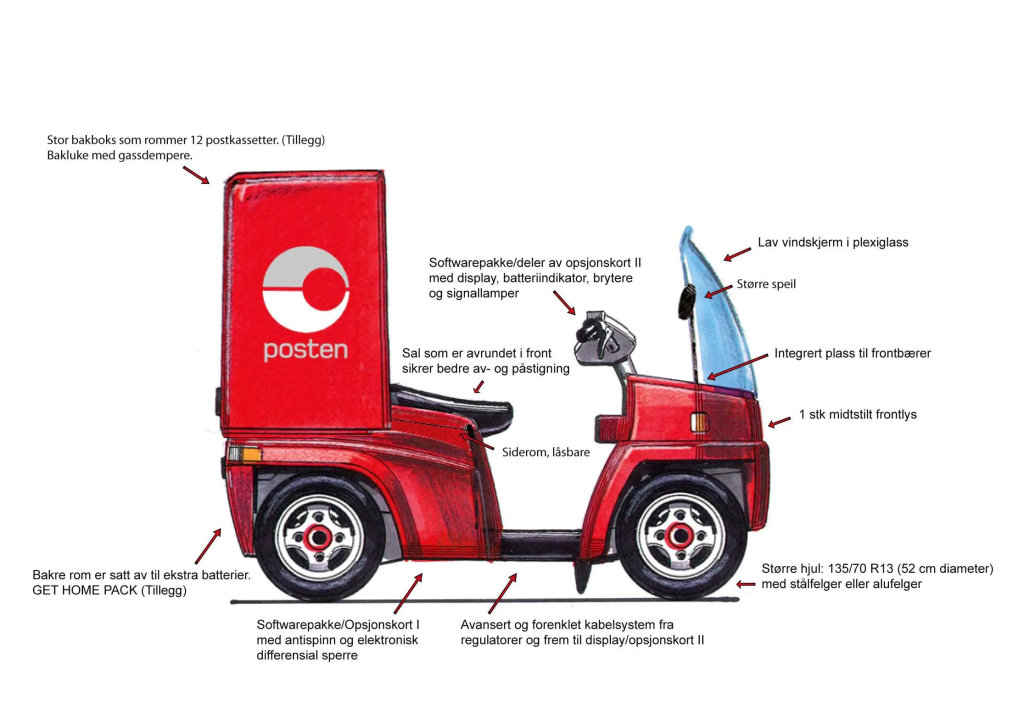

Paxster began as a side-project within Loyds, a supplier of vehicle equipment (but not vehicles) for Norway Post = Posten Norge = the Norwegian post office. It had its facilities in Sarpsborg, a municipality in south-east Norway that has grown into Fredrikstad. When the post office announced some ambitious environmental goals, Loyds started to map how post office vehicles worked. Together they found several challenges about the solutions offered. Some were inefficient, some unprofitable, some both and some neither. They ultimately (in 2013) got approval to work on defining the best ergonomic solutions, together with post-office drivers.

After a few months, the first prototype was ready to test, and adapt, to become a future delivery vehicle for mail, parcels and newspapers.

Bård Eker (1961 – ) through his wholly owned company, Eker Design, designed the vehicle and led to it winning awards for good design. In the autumn of 2013 Paxster was put into production for the Norwegian market.

On July 1st 2015 Paxster was transferred to a separate Aktieselskap (AS) = limited liability company. Since then, Paxsters have been sold in several countries around the world. Paxster claims to be constantly working to develop vehicles to be the best in class when it comes to efficiency, ergonomics and safety.

New Zealand

In 2016, Paxster expanded to New Zealand. New Zealand Post begun rolling out 54 Paxster electric-delivery vehicles in the North Shore district of Auckland as well as the southern town of Oamaru. New Zealand Post has been given permission to use the vehicles on the sidewalks/ footpaths (preferred term in New Zealand) in residential neighborhoods. It was noted that New Zealand Post drivers received safety training, and they are required to give way to all other footpath users.

The fleet grew to 423 in 2018. Initially there were complaints to NZ Post about Paxsters, peaking at 31 in 2018-07. Paxsters were: damaging the grass berm = a narrow ledge or shelf of grass along the top or bottom of a slope, reversing into other vehicles, driving at alleged excessive speed on the footpath.

There were 249 crashes in total with the majority involving a Paxster hitting or being hit by a vehicle or object in 2018, up from 82 in 2017. The number of injuries to posties more than doubled from 36 in 2017 to 80 in 2018. Two of these injuries in 2018 were serious and required professional medical treatment, but the severity of the injuries was less than those in bicycles. A spokesperson stated there were declining costs associated with injuries since the introduction of Paxsters. Compared to bicycles, there were less severe injuries, attributed to the stability of a four wheel vehicle, more efficient braking, greater visibility and more robust protection.

The New Zealand postal union also commented that when the post office introduced the new vehicles they immediately introduced a new roster. Posties on bikes used to work about six hours a day. New rotating shifts for the Paxsters demanded nine-hour days. This increased driver fatigue. New modes of driving on the footpath, and a need to make very quick decisions, contributed to an increase in injuries. Many posties enjoy driving Paxsters but dozens quit when the e-vehicles were introduced. Most of these were long-serving, who preferred to ride a bicycle and felt safer on one. While posties were concerned about the number of injuries, but were more worried about the damage they could do if children sprung out of driveways unexpectedly.

Meanwhile in other parts of Europe…

Later, test vehicles were supplied to the Royal Mail in the United Kingdom, as well as Swedish and German last mile delivery companies. Use of test vehicles have shown that injuries are less severe than when using a bicycle.

History of Automobile Production in Norway

In terms of ICE vehicles: Norsk produced 10 vehicles between 1908 and 1911: a lighter car with a single-cylinder 8 hp engine and a heavier touring car with 4-cylinder engine. Bjering in Gjøvik produced six ICE vehicles between 1920 and 1925. Geijer was even more productive brand and produced about 25 vehicles between 1923 and 1930. Troll made five 2+2 sports cars with a fibreglass body from 1956 to 1958.

In terms of Electric vehicles: About 2 500 Th¡nk cars were produced from 1991 to 2011. There were about 1 500 Kewet (later renamed Buddy) vehicles produced in Økern, Norway, Hadsund, Denmark and Nordhausen, Germany between 2005 and 2013. It is difficult to find out how many were produced where. Of those, 1 087 were registered in Norway.

Some one-off prototypes have also been produced. The one with the most publicity was made by Aetek, a Norwegian company, with the backing of Statoil, now Equinor, the Norwegian government oil company. The FYK, was a Norwegian sports car prototype launched in 2006. It runs on a mixture of hydrogen and natural gas. It was designed as a technology demonstrator, without any plans to put it into series production.

Note: Work began on this post 2021/08/21 at 12:00.