Life is hard; it is harder if you are stupid. John Wayne (Marion Robert Morrison, 1907 – 1979)

Today, I am entering the prophecy business, and, in particular, will be looking at predictions for electric vehicle technology in 2030. Some might question my sanity, or at least my intelligence. Prediction is a double-edge sword. It could result either in adulation (admittedly, a less likely result) or condemnation – perhaps worse (decidedly, more likely). I approach the task fearlessly. If the predictions turn out to be more correct than wrong, rest assured I will remind everyone about it in 2030. If they turn out to be less correct, I won’t bring up the matter again.

Predictions for 2030

- New vehicles in advanced economies will be battery electric vehicles.

- Dynamic wireless charging along main roads will start becoming standard, in addition to static charging at residences.

- Environmentally friendly graphene ultra-capacitors and sodium-ion batteries will start to replace lithium-ion (Li-ion) batteries in most vehicles. Some of these will have a life-expectancy exceeding 1 million km.

- Vehicle owners will have a Right to Repair their own vehicles.

Yes, some of these predictions lack millimetre precision. However, here are a few points of clarification …

- Different markets will achieve different levels of EV penetration at different times, but EVs in all markets will be on their way to displace internal combustion engine (ICE) vehicles.

- Wireless means that plugs will become outdated technology. Dynamic charging refers to charging while a vehicle is in motion. This would probably result in smaller batteries. Commuter vehicles could end up with a battery capacity of about 25 kWh.

- The term battery, as used in this prediction, is intended to include other forms of electrical storage, including the use of various types of capacitors.

- Right to repair does not necessarily mean a right to do-it-yourself (DIY), it could involve local workshops, run by certified mechanics, or even specialists, especially when high voltage is involved.

Previous predictions

Between 1996 and 2002, I took a lot of chemistry and chemical engineering courses, including some related to physical chemistry. At the time I wrote a paper (not lost, just not found) about fuel cells, the technology of the future! At about the same time, General Motors had proven to the world, with the EV1, that there was no future for electric vehicles. The EV1 “was the first mass-produced and purpose-designed electric vehicle of the modern era from a major auto-maker and the first GM car designed to be an electric vehicle from the outset.”

Unfortunately, General Motors was wrong. The documentary film Who Killed the Electric Car? (2006) explains and condemns the short life and brutal death of the EV1. It puts GM in a negative light. There were 660 Gen(eration) I EV1 cars produced, followed by 457 Gen IIs. While a few vehicles were disabled and given to museums and universities, almost all the others were crushed, or shredded.

Could I ever own a GM product? Possibly, in a parallel universe where I am converting a Pontiac Aztek, with a defunct engine, to an EV. But not on this planet. Note: the Aztek is appreciated not just for its utilitarian appearance, but especially for its ability to carry standard sheets of plywood, inside.

I was also wrong about fuel cells taking over the world. Perhaps this too was wishful thinking. With Ballard Power located in Burnaby, the neighbouring municipality to New Westminster, I was well aware of their proton-exchange membrane (PEM) technology, and thought that this would dominate future vehicles. PEMs, more generally, was the topic of my missing paper. Looking at Ballard’s website in 2022, they have not lost their optimism, but seem more focused on heavy transport (buses, commercial trucks, trains, marine vessels) and stationary power applications.

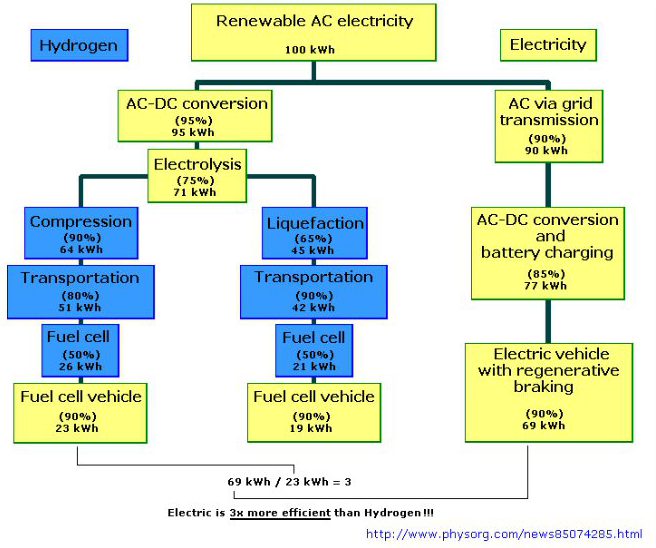

Ulf Bossel (1936 – )has been arguing against Hydrogen technology since 2006. He concluded that Hydrogen technology is unlikely to play a major role in sustainable road transport. This has met with considerable scepticism. Recently, Patrick Plötz, in Nature Electronics 5, 8–10 (2022) confirms that hydrogen fuel cell vehicles, (HFCV), including commercial trucks, are not likely to catch up to battery EVs. Part of the reason is explained in the following diagram, originally developed by Bossel.

The diagram illustrates that FCEVs are three times less efficient, as BEVs. In addition, they require an entirely different (and more expensive) investment in infrastructure. For BEVs, every electrical outlet is a potential charging station.

As I write this, a message from my daughter, Shelagh, California resident and owner of one half of a BMW i3 EV, has just ticked in on the teletype: “I read that 84% [83.7%] of all vehicles sold I Norway in January we’re electric[.]” This statistic refers to the 6 659 battery electric vehicles and the 1 hydrogen fuel cell vehicle sold. Hybrids are excluded, or more correctly, appropriately included with ICE vehicles in the other 16.3% of vehicles sold. Here, there were 910 rechargeable (or plug-in) hybrid vehicles, 175 with power from gasoline and 212 using diesel. These add up to a total of 7 957 vehicles. As the statistics show, there is no longer a sizeable market for ICE vehicles in Norway. From 2025-01-01, all new vehicles under 7.5 tonnes, will have to be EVs (or use fuel cells).

Dynamic charging

If Norway is ahead in cars, Sweden is ahead in roads. Sweden launched the first public electric road in 2016. The electric road outside Sandviken and Gävle utilises overhead lines, which powers freight trucks while driving. eRoadArlanda, outside the Arlanda Airport, provides a test track to generate knowledge and experiences about electric roads.

This was followed up with Evolution Road, a conductive, surface mounted electric road system to increase knowledge about electric roads on a 1-km stretch of road at Getingevägen in Lund, in southern Sweden.

On the Swedish, Baltic Sea island of Gotland, ElectReon is testing a dynamic wireless charging system on a 1.65-km public road, as part of the Smartroad Gotland project. A video demonstrates the construction process. A battery electric (BEV) long-haul truck was the first vehicle to be charged wirelessly. It drove on a 200-meter road segment, at various speeds of up to 60 km/h, averaging a transfer rate of 70 kW, while showing that snow and ice do not affect charging capabilities.

Modern electric road systems provide a number of benefits: the elimination of downtime for recharging – especially important for transit buses, delivery vans, long-haul trucks and robotaxis, reduction of battery sizes by 50–80 per cent (yes, my unscientific estimate is that 25 kWh batteries will be the standard size on EVs once electric roads become common), greater energy efficiency, because smaller batteries mean lighter vehicles, and, most types of electric vehicles: cars, trucks, utility vehicles and buses will be able to use the same system.

Seven years after Sweden, the first stretch of road in the United States to wirelessly charge electric vehicles while in motion will begin testing in Detroit. This electrified road will be up to 1.6 km long, and allow EVs to charge whether they’re stopped or moving. It is hoped that this in-road charging will encourage widespread EV adoption, by reducing consumers EV hesitancy. Michigan state will contribute $1.9 million toward the project, which will also be supported by Ford Motor, DTE Energy and the city of Detroit.

Israel based ElectReon is world leading in terms of dynamic wireless charging. While there are other companies hoping to be part of the solution, they have done little to prove their capabilities. Most potential suppliers of charging equipment are opting for static wireless charging systems in places like parking garages, taxi stands, and bus or truck depots. They should probably take a reality check. Nobody wants to stand still to charge, is the option is to charge while on the move.

It should also be mentioned that there are ongoing dynamic wireless charging pilot projects in Germany, Italy and Israel. All of these use induction technology with on-board receivers facilitating the transfer power from coils buried underground to the vehicle. ElectReon estimates that the cost of a receiver will be reduced to between $1 000 and $1 500, when installed by an EV manufacturer. Another approach is to tie the cost of the receiver to a monthly (?) subscription, that also provides the power.

Terminology.

I find it extremely interesting that one of the celebrated proponents of the International System of Units (SI) was the American electrical engineer, George Ashley Campbell (1870 – 1954). Yet, on an almost daily basis so many Americans, Britons and Canadians (but few others) want to retain all or parts of an antiquated, inconsistent measurement system. Readers have no doubt noticed the avoidance of conventional/ non-metric units, and the usage of SI units on this weblog. However, in this post, some non-SI units will be used. These units are commonly used with EVs throughout the world. I ask for the indulgence and forgiveness of readers.

If one really wants to be correct and use internationally accepted SI units, energy is measured in joules (J). There is also a distinction made between specific energy = massic energy = gravimetric energy density, which specifies energy per unit mass, as in J/kg, and energy density, which specifies energy per unit volume as in J/l (litre). Despite this clear demarcation, most people seem to engage in terminology convergence. They refer to energy density, but express it in terms of watt-hours per kilogram (Wh/kg). Purists may want to remember: 1 Wh = 3600 J = 3.6 kJ.

Batteries and ultra-capacitors

Batteries have come a long way from the invention of the lead-acid battery in 1859 by Gaston Planté (1834 – 1889). Global sales in 2020 = $ 50 billion. These are still ubiquitous, cheap and reliable, but toxic. Finding out exactly how much lead ends up poisoning the environment is difficult. The Battery Council, with close ties to those with vested interests in battery production, typically estimates that 99% of lead is recycled. The United States Environmental Protection Agency has a less optimistic, and more varied estimate that ranges from 60% to 95%. In addition, lead-acid battery recycling is the world’s most deadly industrial process, where an estimated 2 to 4.8 million disability-adjusted life years are lost annually and globally.

In 1989 Sony commercialized the Li-ion battery, and it has become the dominant battery technology. It is the first choice for Evs, stationary batteries, and mobile devices. One challenge with lithium technology, is that it has so many patents and intellectual property rights associated with it, that it becomes problematic to make anything – as a startup. Someone is sure to claim that there is a patent infringement.

Another challenge is availability. Lithium mainly comes from Australia, Chile, China and Argentina. It is also found in smaller quantities in many other places. Extraction is difficult and polluting. It currently costs about $ 5 000 / tonne. Other resources used in lithium (Li) batteries are also problematic. Cobalt (Co), especially. EV batteries can have up to 20 kg of Co in each 100 kilowatt-hour (kWh) pack, or up to 20% of its mass.

There are many other Li-ion battery manufacturers who are also attempting to make new viable products, many with a focus on solid-state Li-ion technology. The reason for this focus is to reduce mass = weight. Unfortunately, this type of battery is almost always years away from being introduced, in part because other battery technologies are always moving the goal posts.

Some social media influencers, such as Sandy Munro, claim that one of the most important Li-ion battery developments in the world at the moment, is taking place at Our Next Energy, Inc. (ONE), located in Novi, Michigan. They have developed an experimental battery, Gemini 001, that stores over 200 kWh of electrical energy, with an energy density of 416 Wh/l, using pouch technology.

Another important development is taking place at Gruber Motors in Phoenix, Arizona. The company is especially important for saving the lives of innumerable bricked Tesla vehicles. It describes itself as an independent Tesla service organization providing engineering and aftermarket support. I refer to Pete Gruber as a guerilla technologist. In a video, he describes their graphene ultra-capacitor cells that now exceed 1 000 km range, and could soon reach 1 600 km. They are estimated to allow about 43 000 charging cycles, with each charge taking about 15 minutes, providing a battery potentially capable of propelling a vehicle exceeding 43 million km, and last 100 years. Graphene is made of a single layer of carbon, one of the most common elements.

The technology upon which the Gruber graphene capacitor is based could be made by Skeleton Technologies of Tallinn, Estonia. This company is providing graphene ultra-capacitor technology to many different industries, including high power applications for automotive, heavy transportation (rail, especially), marine, grid (wind turbines, for example), aerospace, and manufacturing. These use curved graphene sheets to produce mesospores that are accessible to and wettable by ionic electrolytes at voltages up to 4 V. This provides a specific energy of about 85.6 Wh/kg. One characteristic, appreciated in climates with winter, is its ability to operate in cold temperatures, without any performance loss. More information, about a number of technical topics and more, is available from their download page.

Chemical abundance is important when determining the suitability of future technologies for electric vehicle batteries. Here WebElements values will be used for comparative purposes, typically expressed in parts per million (ppm) by mass.Readers who want it expressed in terms of ppm by mole, are encouraged to undertake their own calculations.

Sodium (Na), is the 6th most common element in the Earth’s crust, at 23 000 ppm. In contrast Li ranks 33rd, at 17 ppm. This makes Na over 1 350 times more abundant than Li. This is reflected in its price, at about: $ 150 / tonne. Carbon (C) ranks 17th, at 420 ppm. Not only is this almost 25 times more abundant than Li, its existence in the atmosphere as CO2 makes it an ideal target for battery production.

Na-ion batteries were developed at about the same time as Li-ion batteries. They are suitable for stationary power and short range EVs. That is, applications where energy density is not an issue. For example, energy storage for renewal energy sources such as solar and wind. However, they are not really suitable for hand-held devices.

Like a Li-ion battery they have cathode, anode, porous separator, electrolyte. The same engineering and production methods can be used, but with different materials.

This does not apply to some of the earlier sodium based batteries. Some of the first research projects with sodium batteries were done at the Ford Motor Company where Joseph T. Kummer & Neill Weber published A Sodium-Sulpher Secondary Battery (1968). They state an energy density of 330 Wh/ kg, in contrast to 22 Wh/ kg for a lead acid battery. Later, others have considered this energy density an exaggeration, and have reduced it to about 150 Wh/kg in the real world. The most negative characteristic of this battery was its high operating temperature, 300 – 350 C.

The sodium-nickel-chloride battery, developed under the Zeolite Battery Research Africa Project, started in South Africa in 1985, and commonly called the Zebra battery. This is also a rechargeabe molten salt battery, that distinguishes itself from the Sodium Sulfer battery by it use of commonly available materials. It is simpler, safer, cheaper, but less energy dense, at about 90 to 120 Wh/kg.

From 2010, sodium batteries were developed that could operate at room temperatures. Typically, they have an anode made of hard carbon = charcoal; an electrolyte with low viscosity, high conductivity and electrochemically stable, (typically sodium salts dissolved in organic carbonate); a cathode, often a more problematic choice, but with a focus on sodium layered oxides, with crystalline structure, similar to lithium cobalt oxide (LiCoO

2).

In 2020, Washington State University and Pacific Northwest National Laboratory develop a more powerful sodium battery with the potential to produce 160 Wh/ kg. Other producers of So-ion batteries include: Faradion (UK), Altris AB (Sweden) with a Prussian blue cathodes, HiNa (China), and Natron Energy (USA) with Prussian blue cathodes. Prussian blue cathodes typically offer 95% charge retention after 10 000 cycles; However they do not function well in the presence of moisture, hence Prussian white.

Contemporary Amperex Technology Company Limited (CATL) has also developed a sodium battery. It has an anode made of hard carbon with a unique porous structure that lengthens the cycle lifetime and allows for more sodium-ion movement. The cathode is made of Prussian white, an analogue of the pigment Prussian blue. Energy density is currently 160 Wh/ kg, but there is a goal for G2 = 200+ Wh/ kg. Because of CATL’s intereconnection with Li-ion batteries, only a 10 – 30% price saving can be expected from these batteries.

Right to Repair

Relationships with the service departments of automotive dealers, are not always positive experiences. Going back several years now, here is one customer’s experience of a dealership service centre, that has permanently put him off wanting to use such a place. The customer had replaced original, inferior wiper blades with premium blades that were still in excellent condition when he delivered his vehicle in for servicing. When, the car was picked up, those premium blades had been replaced with inferior blades, and the customer was charged a price for them that exceeded those of the premium blades. When the customer requested the inferior blades removed, and replaced with his premium blades the dealership refused, citing that the manufacturer, required them to perform servicing to the letter, in order not to void the warranty. Wiper blades were part of the required service. The customer then asked for the premium blades to be returned to him, but the dealership could not find them.

Some weeks later, an indicator light showed that the vehicle needed immediate servicing, and should not be driven. The dealership was contacted, and they picked up the vehicle, transporting it on the back of a tow truck (a 70 km round trip from the workshop). It turned out that the dealership had forgotten to reset the servicing interval when they undertook the service, indicating that they were not following the servicing guide to the letter, as they had previously claimed. They then had to transport the vehicle back to the customer on the back of the same tow truck, two days later.

Shortly thereafter, a fuel injector failed on the vehicle (for a second time). Once again, a tow truck was needed to transport the vehicle, which was at the customer’s place of work. This time it involved a 160 km round trip, followed by a 70 km round trip after replacement. The fuel injector had to be replaced under warranty, and the customer wondered if the dealership had failed to do something else during the servicing, that had resulted in this failure. Some months later, the vehicle warranty expired, and the customer ended his relationship with the dealership. These incidents were so traumatic that the customer vowed never to buy that brand of vehicle again.

With EVs a different experience of service may be offered. EVs have fewer parts in total, and fewer moving parts, the operating environment is less extreme because there is no combustion to produce excessive amounts of heat. Thus, EVs typically require less service than their ICE counterparts. While legacy auto-makers may attempt to continue on as before, EV startups will probably be less reliant on dealerships, and more reliant on websites, for sales. They may also attempt to approach service and repairs in a different way.

Take Sono Motors GmbH as an example. Sono is a crowdsourced German company working on the development of the electric solar car, the Sion. It will have solar cells embedded in the plastic body panels on the roof and sides. Electricity generated will be fed into the traction battery, potentially providing about 5 000 km of range per year. Over an eight year period, over 260 000 vehicles are expected to be produced in Trollhättan, Sweden, at the National Electric Vehicle Sweden (NEVS) production facility. NEVS is a Swedish electric car manufacturer that acquired the assets of Saab from a bankruptcy estate in 2012.

There are currently about 13 000 customers waiting for production of the Sion to start. Potential purchasers are distributed (almost) randomly throughout Europe. This could mean that it would be very expensive for Sono to set up service centres. Fortunately, they have opted for something different: Low Cost Maintenance, with a 3-step maintenance system they claim will keep repair/ servicing costs as low as possible.

- Standard replacement parts that can be replaced by almost anyone. That is, without needing much prior knowledge, these can be replaced by owners/ users. Sion says, DIY is back!

- A workshop handbook, will allow an extensive network of independent mechanics, to undertake work that is beyond the capability of ordinary people. This is the essence of most Right to Repair legislation.

- For repairs involving high-voltage or body parts, Sono intends to cooperate with an established European service provider.

Once one auto-maker has shown the viability of this approach, it will be difficult for others to avoid step #1. As shown previously, one of the challenges facing dealerships is that they are not behaving particularly professionally, when it comes to servicing vehicles. Another challenge in the future, is that there will be a shortage of workers available. Work that can be eliminated or reduced should be. Ron Hetrick explains what is happening in USA, but the same applies to other advanced economies.

Currently, I rank Sono Sion as my third choice for an EV. Above these are two families of MPVs: the upcoming Renault Kangoo, and its badge engineered Nissan Townstar, along with an upmarket Mercedes EQT; and the Stellantis MPVs: Citroën Berlingo, Peugeot Rifter and Opel Combo, badge engineered variants.

EV Tipping Points

In 1989, A-ha lead singer Morten Harket and keyboardist Magne Furuholmen, were in Switzerland with Norwegian environmentalist Frederic Hauge, attending an EV conference. After inspecting a privately converted Fiat Panda EV, Harket and Furuholmen bought the car, and took it back to Norway. Norwegian regulations at the time, prohibited the registration of electric cars. Since it was fitted with a propane-fuelled heater, it could be, and was, registered as a recreational vehicle/ motor home.

The Panda was enthusiastically driven around Oslo, without paying local road tolls and ignored all subsequent fines. This resulted in an enormous amount of publicity, in Norway. It also resulted in the car being confiscated, and auctioned off, with yet more publicity. However, since no-one else wanted to buy the car, the original owners bought it back again. This cycle repeated itself several times. The fine was NOK 300 each time, and they bought the car back each time for NOK 200.

In 1996, Norway’s Government abolished road tolls for EVs. This was a key incentive that started an EV policy, that resulted in generous subsidies and other incentives, leading to a situation where over 80% of all new light vehicles are EVs in 2022.

Tim Lenton, at the University of Exeter, is quoted in the Guardian as saying: The only way we can get anywhere near our global targets on carbon emissions and biodiversity is through positive tipping points. People, whether they’re business leaders, policymakers or whatever, know what needs to change. The question is how? It’s starting to happen, but it’s not going quick enough. The complexity [of the climate and ecological crises] can be paralysing,. I wanted to show that, if you understand the complexity, it can open up windows of opportunity to actually change things.

An analysis of this problem has been published in Global Sustainability.

Predictions, in general

I hope that my legacy as a person is not dependent on my ability to predict the future. Rather, I hope it is related to my ability to love a few people, and to show concern for the well-being of all of humanity and the planet more generally, now and into the future. Hopefully, I have learned something, including humility, from my years of living.

When it comes to judging the success or failure of predictions, I like to turn to the world of film, especially works set in the future. I am not a fan of either Gene Roddenberry’s (1921 – 1991) Star Trek, despite its debut on Canadian CTV on 1966-09-08 and set in the 23rd century, or George Lucas’ (1944 – ) 1977 Star Wars and successive films, taking place a long time ago in a galaxy far, far away, which excludes it from being set in the future. More appreciated are: Lucas’ 1967/ 1971/ 1977/ 2004 THX 1138; Stanley Kubrick’s (1928 – 1999) 2001: A Space Odyssey (1968), and A Clockwork Orange (1971); Richard Fleischer’s (1916 – 2006) Soylant Green (1973) set in 2022; Michael Anderson’s (1920 – 2018) Logan’s Run (1976), set in 2274. Perhaps most of all, I admire Ridley Scott’s (1937 – ) Blade Runner (1982), set in Los Angeles in 2019, 37 years into the future, and currently three years in the past, if only because of its inability to predict the advent of the cell phone.

Yet, of these, it is Soylant Green that is the most haunting, and to where the political class seems to be leading the world: dying oceans, excessive humidity, pollution, overpopulation, depleted resources, poverty and – ultimately – euthanasia.

If one focuses on one random member of the political class – no better nor worse than many of the others – Joe Biden (1942 – ) born in Pennsylvania, the state where USA’s first oil well was drilled in 1859. He grew up in Delaware, where his father ultimately worked as a successful used-car salesman. In 2018, the US became the world’s largest crude oil producer (15%), exceeding Russia and Saudi Arabia. In 2021, some sources state that this resulted in 10.3 million jobs, and 8% of USA’s gross domestic product (GDP). Oil companies are major contributors to politicians, in the expectation that they will act positively to the needs of these companies and their shareholders. Chevron made 28% of its $4.9 million in political contributions to Democratic candidates and party, while Exxon made 41% of $1.7 million contributions to them.

Not everyone is happy with him. It is very strange that Biden can mention the electrification efforts at GM and Ford, without mentioning Tesla. Unfortunately, this could be because he is more interested in the profits of the oil industry, that are dependent on ICE vehicles from GM, Ford and others. Biden was willing to auction off 320 000 square kilometres of oil leases in the Gulf of Mexico, making it the largest sale in US history, although only slightly less than 7 000 square kilometres were ultimately leased, yielding $192 million. So far, Biden is approving 320 drilling permits on public land each month, exceeding Trump’s 300 a month.

This support of the oil industry does not in any way mesh with a necessary reduction in greenhouse gas emissions, that climate in crisis requires. Indeed, Biden’s environmental policy, if it exists, is difficult to understand. It seems to begin and end in words. The stated aim is a halving of greenhouse emissions by 2030, with them reaching net zero by 2050.

USA has many American EV manufacturer, to be appreciated. Aptera has the most efficient EVs; Arcimoto is making fun utility vehicles (FUVs); the Fisher Ocean should appeal to anyone wanting a conventional SUV; Ford has had great success with its Mustang, and sees promise in its upcoming F-150 Lightning; Rivian has started to provide adventure pickups and SUVs; Tesla is making the most EVs; and, last and least, General Motors is making an excessive, large and brutal Hummer EV that effectively shows that not all EVs benefit the world!

As John Wayne says, life is hard. It will be harder still for all people, smart or stupid, if politicians stupidly fail to implement environmental policies that stop the current rise in temperatures. This includes the elimination of fossil fuels, and fossil plastics, that are burnt as fuels once their few seconds of shelf-life are finished. The four predictions discussed in this weblog post, are all dependent on politicians enabling people to make enlightened changes to their ways of life, quickly! Most of those changes will have to take place now in advanced economies. If people alive today don’t start making changes to their lifestyle, the lives of upcoming generations will be immeasurably harder.