Wood screws are preferred connectors in wood work spaces. They are strong, and allow connections to be made between parts made from solid wood, as well as sheet goods such as MDF and plywood. They eliminate the need for complex joinery. They have uses from the start to finish of a build, from jig and form construction through to mounting hardware and trim.

Screws are available in a variety of metals: aluminum, brass, silicon bronze and stainless steel. While there can be reasons for using something other than steel, including non-magnetic, corrosion resistance and decorative attributes, steel screws are the most useful for wood projects. Attributes include affordability, availability in a range of shapes and sizes, durability and strength.

Drywall screws are used by many wood workers. These are made from a relatively hard steel, allowing them to be driven in quickly, without pilot holes. They are often chosen because they are inexpensive. Unfortunately, they are also brittle and may snap. For projects requiring strong connections, they are a poor choice.

Production screws are hardened with sharp and strong points and threads capable of penetrating hard woods and other materials, including some metals. Their heads and shanks can withstand high torque driving with a power drill or impact driver, and can withstand stresses commonly experienced in furniture. Unfortunately, they are not weather resistant. Deck screws are production screws that have been plated and/or coated to increase corrosion resistance.

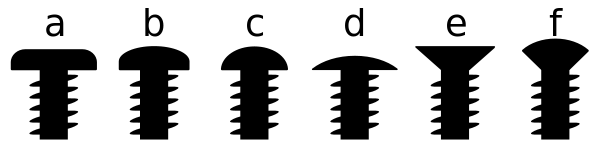

Several types of heads are available. Pan heads have a low disc with a rounded, high outer edge with large surface area. Button or dome heads are similar to pan heads, but with a more rounded top. These are not commonly used. Round heads have a decorative dome-shaped head. These are not designed to be used structurally. Truss or mushroom heads are specifically designed to prevent tampering. Flat or countersunk heads are conical, with a flat outer face and a tapered inner face. It is designed to sink into the material. Oval or raised heads are decorative with a countersunk bottom and rounded top. Of these the countersunk head is the most common in woodworking. Where a large surface area is needed for structural purposes, a pan head is used, with or without a washer, to increase the area.

As a Canadian, I used Robertson screws when I built my first sailboat in 1962-3. There were two qualities that made these an appropriate choice: stick fit and cam-out resistance. Stick fit is the ability of the driver to hold onto the screw without human intervention. This frees a hand but, more importantly, it allows screws to be driven into hard-to-reach places. Cam out is a problem with Phillips screws, especially. When torque exceeds a screw’s capacity the driver will slip out of the head of the screw.

Star (aka Torx) drives offer the same advantages as Robertson drives. Since these are universally available in Norway, these are preferred drives for woodworkers willing to make rational choices.

Standard screws at Unit One are Heco TFT Woodscrews, which can be used for interior and exterior purposes. They are in corrosion class 4, made of herded steel.

Standard sizes are: (Torx 20) 4.0 x 30, (Torx 25) 5.0 x 40, 5.0 x 60, (Torx 30) 6.0 x 90 and 6.0 x 160.