Version 2: Includes the conclusion left out of Version 1, and some corrections.

Does the world really need another meaningless abbreviation: DM&D? Probably not, but abbreviations are cheap, and give the impression that there are many users embracing the term, and the term is used so often that it is necessary to abbreviate it. The University of Buffalo, through Coursera (The MOOC organization) is offering courses in “Digital Manufacturing & Design”. They referred to something called opendmc.org (where dmc appears to stand for Digital Manufacturing Commons). This site only provides cryptic error messages, until one finds www.portal.opendmc.org, after which it is indeed possible to explore some of the site and meet a bunch of dead ends. Finally, one stated: “Our platform is currently in a closed beta.” So much for the openness of opendmc.org.

Now, the main reason I actually visited the site was to find out what distinguishes DM&D from CIM, Computer Integrated Manufacturing. This latter term has gradually won favour in all sorts of environments. It has been in continual use since 1973, with the publication of Joseph Harrington’s book, Computer Integrated Manufacturing. It has become the preferred term since 1984 when computer-integrated manufacturing actually began, promoted by machine tool manufacturers, and CASA/SME or the Computer and Automated Systems Association and the Society of Manufacturing Engineers. So why change?

In a quest for greater insight and illumination (in the more abstract sense of the term) I turned to Wikipedia, and their article on Digital manufacturing: “Digital Manufacturing is an integrated approach to manufacturing that is centered around a computer system.” This sounded suspiciously like CIM, just with a more abstract digital replacing the more concrete computer. Yet more enlightenment followed, “Overall, digital manufacturing can be seen sharing the same goals as computer-integrated manufacturing (CIM), flexible manufacturing, lean manufacturing, and design for manufacturability (DFM). The main difference is that digital manufacturing was evolved for use in the computerized world.” One could only ponder. Does computer-integrated manufacturing only exists in some non-computerized world? Perhaps CIM is only some form of primitive virtual reality. Readers are left to cogitate: Digital Manufacturing is Computer-Integrated Manufacturing evolved for use in the computerized world.

What could be better than cloud computing, except cloud-based manufacturing? The same Wikipedia article on Digital Manufacturing, states: “Cloud-Based Manufacturing (CBM) refers to a model that utilizes the access to open information from various resources to develop reconfigurable production lines to improve efficiency, reduce costs, and improve response to customer needs.”

That quoted text contains any number of insights (although the most probable number is 0). Unfortunately, this reader lacks the ability to understand what the text actually means. Could women and men of insight please help me understand this text? I would be eternally grateful. Yet, inside of me, I know there is nothing to understand. These are simply empty words.

The major challenge with texts about computer/digital manufacturing is the role to be played by people. Dark factories want to prohibit people from even entering them, at least during the manufacturing processes. At the other extreme, there is the growing field of collaborative robotics which in some way wants to hook up (as it were) humans and robots in the workplace.

As expected, trade unions are pressing for a humanized working environment. Tim Page writes in The Fourth Industrial Revolution: a breakthrough that must be humanized, ” So we must put people at the heart of digital manufacturing. The German engineering union IG Metall has developed some clear priorities for the introduction of this production revolution. Alongside Industrie 4.0, the German name for digital manufacturing, IG Metall have called for Arbeit/Work 4.0. This should include:

- Job security and fair remuneration

- A reduction of workload

- A revaluation of activities

- Better professional development and learning opportunities;

- More time sovereignty

- Informational self-determination

- Involvement and participation on an equal footing

The introduction of digital manufacturing must be accompanied by the relentless quest for new jobs, better jobs, empowering jobs. The German approach, introducing this with the full involvement of the future labour force, is the right approach. It means working constructively with trade unions and other civil society organisations. ” http://touchstoneblog.org.uk/2016/11/fourth-industrial-revolution-breakthrough-must-humanised/

These are all very nice sentiments, but the pathway from “Industrie 3.9” (or where ever we are now) to 4.0 is unclear.

Martin Ford in Rise of the Robots: Technology and the threat of a jobless future, sketches a new economic paradigm in his tenth, and last, chapter. He writes about diminishing economic returns from education, cites Nicholas Carr’s The Shallows, which Ford regards as anti-automation. He then writes warmly about a basic income guarantee, especially from Friedrich Hayek’s perspective. This warmth continues as he writes about markets as renewable resources. Many other proposals are taken up, but in the end Ford presents no other solution than a basic income, bread and circus for the 21st century. Even though I gave it a 5 on Goodreads, the last chapter of Ford’s book was a depressing read.

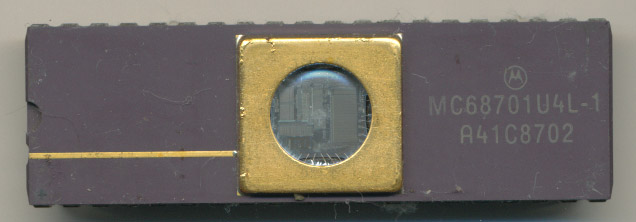

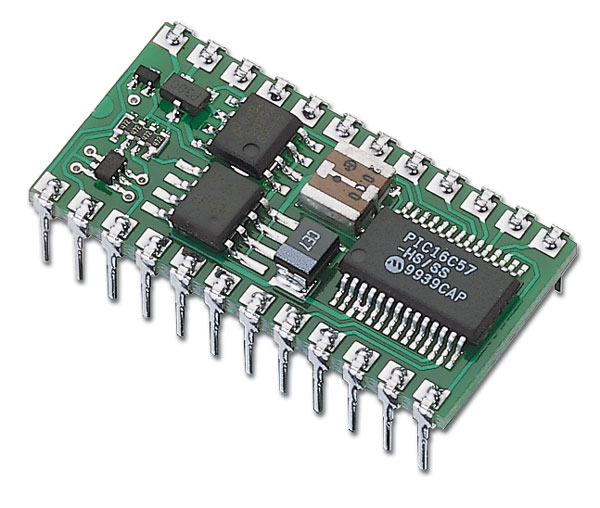

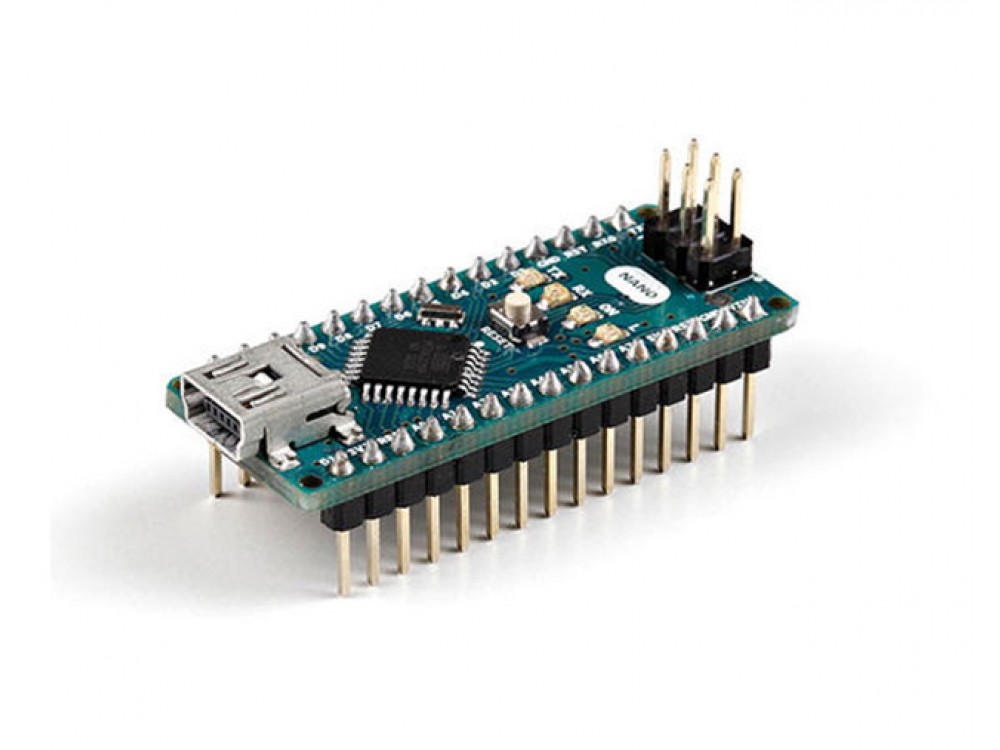

There seems to be no need for yet another phrase (digital manufacturing) to replace Computer Integrated Manufacturing. Yes, manufacturing processes have matured, or at least aged, these past 45 years, but that is no reason to discard a perfectly good term. We still call a 2017 laptop a computer, even if it differs significantly from a Digital Equipment PDP-11/20 mini-machine from 1970.

https://en.wikipedia.org/wiki/Digital_manufacturing